Volume of ore from underground mining now exceeding steady-state monthly requirements of the Phase 1, 3.8-Mtpa concentrator

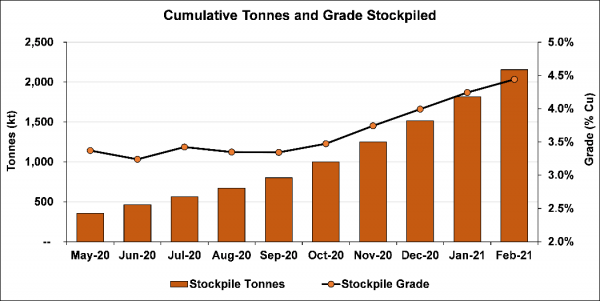

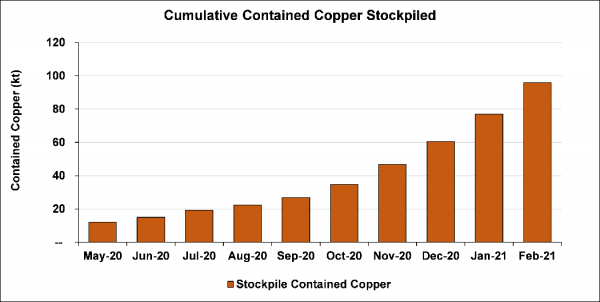

Pre-production ore stockpiles now hold 2.16 million tonnes grading 4.44% copper, containing more than 95,000 tonnes of copper

Major conveyor belt changeover to permanent configuration completed in February, with underground ore now directly delivered to the surface stockpile

Overall progress of Kamoa-Kakula’s first phase, 3.8-Mtpa mining and milling operation now 78% complete; initial commissioning underway at the concentrator and first copper production on track for July 2021

Phase 2 expansion to 7.6 Mtpa progressing well toward a Q3 2022 start-up

Potential for sustained higher copper prices further improves outstanding project economics

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun are pleased to announce that underground ore production at the Kamoa-Kakula Copper Project in the Democratic Republic of Congo (DRC) has for the first time exceeded the steady-state requirements of the Phase 1, 3.8-million-tonne-per-annum (Mtpa) concentrator plant. In February, the project mined and stockpiled 339,000 tonnes of ore grading 5.50% copper from the Kakula and Kansoko mines. The tonnage was 13% higher than January, while the copper grade continued to trend higher.

The new production record in February was achieved even with undertaking the scheduled conveyor belt changeover to the permanent configuration at the Kakula Mine, which limited underground ore haulage for one week.

The 339,000 tonnes mined in February include 47,300 tonnes grading 4.62% copper from the Kansoko Mine, establishing a new monthly production record at Kansoko. The total tonnage mined also includes 107,000 tonnes grading 9.01% copper from the high-grade centre of the Kakula Mine.

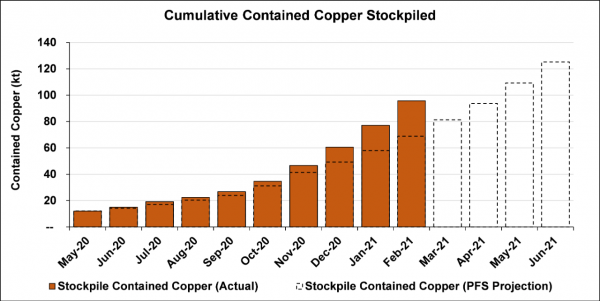

The project’s pre-production surface stockpiles now contain approximately 2.16 million tonnes of high-grade and medium-grade ore at an estimated blended average of 4.44% copper. Contained copper in the stockpiles increased by approximately 19,000 tonnes in February – a 19.2% increase over January’s production – to a cumulative total of more than 95,000 tonnes (the current copper price is approximately US$9,100 a tonne).

Kamoa-Kakula is on track to have more than three million tonnes of high-grade and medium-grade ore stockpiled on surface, holding more than 125,000 tonnes of contained copper, prior to the planned start of processing in July 2021.

George Gilchrist, Ivanhoe Mines’ Vice President, Resources (left), and Franck Twite, Kamoa Copper’s Senior Supervisor Geology (right), mapping an ultra-high-grade ore zone at Kakula. The dark gray layers of chalcocite ore contain approximately 10% copper based on results from nearby channel sample profiles.

Potential for sustained higher copper prices draws attention to the project’s exceptional economics using long-term copper prices of US$4.00/lb and US$4.50/lb

In September 2020, Ivanhoe published outstanding economic results of the independent Integrated Development Plan 2020 (IDP20) for the Kamoa-Kakula Copper Project. The IDP20 comprised three development scenarios: Kakula definitive feasibility study (DFS) at a mining rate of 6 Mtpa; Kakula-Kansoko pre-feasibility study (PFS) at a mining rate of 7.6 Mtpa, and Kamoa-Kakula preliminary economic assessment (PEA) at a mining rate of 19 Mtpa. The base case, long-term copper price used in the IDP20 was US$3.10 per pound (lb), on a real basis.

Since the IDP20 was published, spot copper prices have surged to new nine-year highs of more than US$4.30/lb. While this surge has not yet changed long-term copper price assumptions, this warrants a closer look at the long-term copper price sensitivities published at the time of the various development scenarios using long-term copper prices of US$4.00/lb (US$8,818/ tonne) and US$4.50/lb (US$9,921/tonne), given the potential now for sustained higher copper prices.

The Kakula 2020 FS highlights that a mining rate of 6 Mtpa yields an after-tax NPV8% of US$5.5 billion and IRR of 77% at a long-term copper price of US$3.10/lb, rising to US$8.4 billion and IRR of 100% at a copper price of US$4.00/lb, and US$9.5 billion and 106.9% at a copper price of US$4.50/lb.

The Kakula-Kansoko 2020 PFS highlights that a mining rate of 7.6 Mtpa yields an after-tax NPV8% of US$6.6 billion and IRR of 69% at a long-term copper price of US$3.10/lb, rising to US$10.5 billion and IRR of 93% at a copper price of US$4.00/lb, and US$12.0 billion and 99.8% at a copper price of US$4.50/lb.

The Kamoa-Kakula 2020 PEA highlights that a mining rate of 19 Mtpa yields an after-tax NPV8% of US$11.1 billion and IRR of 56.2% at a long-term copper price of US$3.10/lb, rising to US$18.1 billion and IRR of 79.9% at a copper price of US$4.00/lb, and US$20.9 billion and IRR of 89% at a copper price of US$4.50/lb.

“We’ve been publicly stating for the record confidence about higher copper prices in real terms for a long time. The stars now are aligning for the start of production at Kamoa-Kakula,” said Mr. Friedland. “We believe we’re only on the cusp of what will be a structural, powerful and long-term commodity rally given supply limitations and fundamental demand from global green initiatives.”

“The economics for pushing ahead with the Phase 3 and 4 expansions to bring the project’s mining rate to 19 Mtpa are compelling,” Mr. Friedland added. “At this expanded rate, Kamoa-Kakula will rank as the world’s second largest copper producer, with peak annual copper production of more than 800,000 tonnes. Our team has only scratched the surface on our massive, 100%-owned exploration licences in the adjoining Western Foreland region that shares virtually identical geology to Kamoa-Kakula and is the focus of an expansive exploration campaign from this year onwards.”

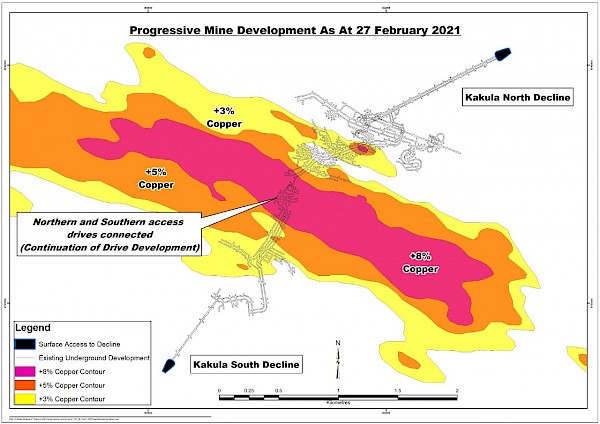

Underground mine development remains well ahead of schedule, providing the confidence to push forward with Kamoa-Kakula’s Phase 2 construction

February’s advancement of 2,798 metres brings total underground development to approximately 35.5 kilometres – around 12.4 kilometres ahead of schedule. The monthly underground development in February was comprised of 2,389 metres at the Kakula Mine and 409 metres at the Kansoko Mine.

Drift-and-fill stoping operations are progressing well at the Kakula Mine, with approximately 70% of January’s ore production coming from stoping operations and the remainder coming from mine development activities. Drift-and-fill stoping is a highly-productive mining method of extracting underground ore, where a single tunnel, known as a stope, is extracted leaving an open void that is subsequently backfilled to allow for the extraction of the neighbouring stope in sequence.

Mark Farren, Kamoa Copper’s CEO, commented: “An outstanding performance in February under some challenging circumstances, given that we completed a major conveyor belt changeover at Kakula. The changeover slowed underground development and load-and-haul operations, as the underground tips could not be used for a week and ore had to be trucked to surface. Despite the temporary conveyor-related slowdown, we saw a strong mining performance with record tonnes and copper grade delivered to surface stockpiles.”

“We continue to successfully mine the high-grade stoping areas in the center of the Kakula Mine at selective cuts of approximately 10-metres high by 7.5-metres wide in a single pass. This bulk mining method is enormously beneficial as it generates large-volume, high-grade ore blocks that can be mined selectively,” Mr. Farren added.

Jumbo drill in operation in a 10-metre-high by 7.5-metre-wide high-grade stoping area in the central part of the Kakula Mine.

Mine geologist Micheline Kyenge showing the ultra-high-grade chalcocite ore in the Kakula central area that is averaging more than 8% copper.

Auto electrician Raul Mwenze – one of thousands of bright, young Congolese who are helping transform Kamoa-Kakula into the world’s next great copper mine.

Kansoko’s ore mined in February was approximately 47,300 tonnes at an average grade of 4.62% copper. The tonnage was 82% higher than achieved in January and the average copper grade was 7% higher. Kansoko now has introduced a third mining crew, and is ramping up production. Kansoko will be an important part of the production mix for the Phase 2 concentrator plant when it begins operations – currently planned for Q3 2022.

Phase 1 copper production from the Kakula Mine is scheduled to begin in July 2021. Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated early average feed grade of more than 6.0% copper, ramping up to 7.6 Mtpa in Q3 2022. Phases 1 and 2 combined are forecast to produce up to approximately 400,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

A 2020 independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the Government of the Democratic Republic of Congo (20%).

Mechanic Landry Moma Twite performing maintenance on a jumbo drill rig at the Kakula North heavy equipment workshop.

Construction is advancing rapidly on the concentrator equipment workshop (left) and storehouse (right).

The bulk reclaim tip at the Kakula Mine is nearing completion.

February’s ore production was 13% higher than January at slightly higher grades; pre-production surface ore stockpiles now total approximately 2.16 million tonnes grading 4.44% copper

Chart 1: Cumulative tonnes and grade of pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to February 2021.

Chart 2: Growth in contained copper in pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to February 2021.

Chart 3: Projected growth in contained copper in pre-production stockpiles at the Kakula and Kansoko mines up to July 2021. Dotted lines denote projections based on the 2020 pre-feasibility study.

The ore being mined from the northern portion of the Kakula Mine is transported to surface via the conveyor system and placed on a blended surface stockpile that now contains approximately 1.23 million tonnes grading an estimated 4.65% copper.

Additional pre-production ore stockpiles are located at the Kakula southern decline (677,000 tonnes at a blended grade of 4.47% copper) and the Kansoko decline (251,000 tonnes at blended grade of 3.31% copper).

Kakula’s main pre-production stockpiles at the northern declines. The blended stockpiles currently contain approximately 1.23 million tonnes grading 4.65% copper.

Kakula southern decline blended ore stockpiles containing approximately 677,000 tonnes grading 4.47% copper (consisting of 341,000 high-grade tonnes @ 6.10% copper and 336,000 medium grade tonnes @ 2.81% copper).

Kansoko decline blended ore stockpiles containing 251,000 tonnes grading 3.31% copper (consisting of 35,000 high-grade tonnes @ 5.56% copper and 216,000 medium-grade tonnes @ 2.95% copper).

Figure 1: Underground development completed at Kakula Mine to February 27, 2021 (in black).

Construction of the initial 3.8-Mtpa concentrator plant and other surface infrastructure now 78% complete; first stage of commissioning underway; earthworks and civil works progressing well for the second 3.8-Mtpa concentrator plant

Overall progress of Kamoa-Kakula’s first phase, 3.8-Mtpa mining and milling operation (covering mine infrastructure, concentrator plant and surface infrastructure) now is approximately 78% complete, compared to 71% in January. Overall construction of the project’s first phase, 3.8-Mtpa concentrator plant and associated facilities is advancing rapidly and is approximately 62% complete, up from 43% complete last month. The concentrator plant remains on track to be mechanically complete in Q2 2021, with first copper concentrate production scheduled for July 2021.

Delivery of equipment for the first concentrator plant is nearing completion with more than 2,370 truckloads of equipment and material having been delivered to site. The last shipments of switchgear and transformers for emergency power are scheduled to arrive in March and April 2021, respectively. The first shipment of the sand filter has arrived, with the remaining shipments expected in March.

Structural steel erection and platework installation for the first concentrator plant is effectively complete. The structural, mechanical, piping and platework (SMPP) contractor now is focused on piping and valve installation; this is nearing 70% completion.

Civil works for the first concentrator plant is effectively complete and the civil contractor now is focused on the Phase 2 concentrator plant, with work progressing in most areas.

Electrical, controls & instrumentation (EC&I) installation is the last activity before construction completion and subsequent commissioning. Cable installation and cable termination is well advanced, with more than 150,000 metres of copper cable installed out of a total of 207,000 metres (207 kilometres). The installation of instrumentation is well underway and the energizing of the concentrator plant with medium-voltage power is scheduled for the end of March 2021.

Punch listing and the first stage of commissioning (C1 – construction/mechanical complete) has started with a number of areas of the concentrator plant deemed “construction complete”. During the first stage of commissioning, the plant is not energized with electrical power. The next stage (C2 – pre-commissioning) of plant commissioning will see the plant energized for motor, instrumentation and control system electrical checks.

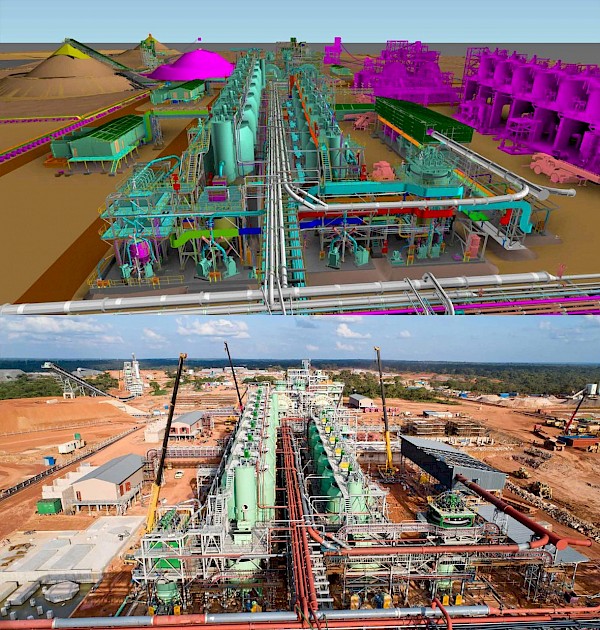

A 3D illustration of Kakula’s initial 3.8-Mtpa concentrator plant, with the recently-initiated Phase 2, 3.8-Mtpa processing plant shown in magenta. The picture below shows the currentconstruction progress. The plant’s flotation cells (green) and ball mills (yellow) are more than 85% complete and first-stage commissioning has begun.

Electrical installation at the backfill plant is well advanced and construction completion is expected at roughly the same time as the processing plant. The backfill plant is scheduled to be complete well before paste backfill is required for mining operations.

The backfill plant will be used to mix tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage.

Construction of the tailings storage facility is progressing well and is scheduled to be completed well ahead of the required date.

Construction of the second 3.8-Mtpa concentrator plant is progressing well with the current focus on earthworks and civil works. Both earthworks and civil works are tracking slightly ahead of schedule. With orders for all the long-lead items of equipment for the Phase 2 concentrator placed in September 2020, procurement activities have focused on the remainder of the plant equipment. The contract for structural steel supply has been placed and the SMPP erection contract is under negotiation.

Construction of the secondary crushing building now is complete.

A 3D illustration of the finished ball mills area for the Phase 1, 3.8 Mtpa concentrator, with the next two ball mills for the recently-initiated Phase 2 concentrator plant shown in magenta. The picture immediately below shows the current construction progress.

The Phase 1 tailings and concentrate thickeners are more than 90% complete, and work is underway for the foundations for the Phase 2 thickeners (red circle).

Workers installing an impermeable liner on the raw-water storage reservoir that will supply process water to the concentrator plant.

A 3D illustration of Kakula’s first phase, finished backfill plant, with the current construction and the initial 3.8-Mtpa concentrator plant in the background shown immediately below.

Ongoing construction of the concrete foundations for the ball mills for the second 3.8-Mtpa concentrator plant.

Pouring concrete foundations for the Phase 2 concentrator flotation cells.

Discussions for the marketing of Kakula’s copper concentrates nearing completion

Kamoa-Kakula is nearing the completion of agreements with respect to the sale of its copper concentrates during Phase 1 operations. Kakula is expected to produce an extremely high-grade and clean copper concentrate (containing over 55% copper) that will be highly coveted by copper smelters around the world. Metallurgical test work indicates that the Kakula concentrates contain extremely low arsenic levels by world standards – approximately 0.01%.

Kamoa-Kakula connected to 220-kV national electrical grid; the first of six turbines at the refurbished Mwadingusha hydropower plant now synchronized to the national electrical grid – providing clean, renewable hydropower

In December 2020, the 35-kilometre-long double circuit 220-kilovolt (kV) power line to Kamoa-Kakula was connected to the national electrical grid through theNew Western Dispatch (NRO) substation in Kolwezi. Kamoa-Kakula’s main 220-kV substation is nearing completion and is expected to be energized by the end of March.

Ivanhoe Mines Energy DRC also announced that the first of six new turbines at the Mwadingusha hydropower plant was synchronized to the national electrical grid in December 2020. The commissioning of the hydropower plant’s remaining five generating units, in sequence, is in progress. This will ensure that Kamoa-Kakula’s power requirements are secured ahead of the commissioning of the concentrator plant.

The fully-refurbished Mwadingusha hydropower plant is expected to deliver approximately 78 megawatts of power to the national electrical grid.

COVID-19 prevention and treatment initiatives enhanced while maintaining risk management strategy

Kamoa-Kakula continues to focus on prevention, preparation and mitigation in managing the risks associated with COVID-19. Large-scale testing, combined with focused preventative measures, ensures that positive cases are quickly identified, isolated and treated, with cross contamination kept to a minimum.

The project has a well-established COVID-19 isolation facility at the Kamoa Camp. Suspected cases and positive patients are moved to this facility, where they are isolated and treated. Once patients have recovered and are deemed no longer infectious, they can return to work only after an additional quarantine period determined by the project’s medical staff.

Kamoa-Kakula has successfully treated a number of symptomatic patients in the Kamoa Hospital, where highly-experienced doctors and nurses apply the latest medical treatments in a world-class facility.

As the pandemic evolves, the medical team at Kamoa-Kakula continues to review and update its risk mitigation protocols, while ensuring that new medical advances are investigated and applied to protect the health and safety of the workforce and community members.

(Left to right) John Grech (millwright), Guy Nkunda Mvamba (mechanic), Benoit Mpungwe (mechanic), Gert Strydom (millwright) and Alain Lukusa Bonolo (auto electrician) at the Kakula North heavy equipment workshop.

Doralie Kona, Kamoa Copper’s Specialized Administrator, Construction/Projects, in the Kamoa North offices.

Mulopwe Bunda (left) and Alain Mukoj (right) inspecting cabbage plants at a local community garden– a Kamoa-Kakula sustainability initiative to build and support successful food-production activities in nearby communities.

Mapinji Kabwita, a Kamoa Copper employee, tending to oranges at the Kamoa-Kakula Livelihoods demonstration garden.

Residents of the village of Chinde Chinde collecting fresh water from a new community borehole, another Kamoa-Kakula sustainability initiative.

Qualified Persons

Disclosures of a scientific or technical nature regarding development scenarios at the Kamoa-Kakula Project in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Amos is not considered independent under NI 43-101 as he is the Head of the Kamoa Project. Mr. Amos has verified the technical data disclosed in this news release.

Other disclosures of a scientific or technical nature regarding the stockpiles in this news release have been reviewed and approved by George Gilchrist, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Gilchrist is not considered independent under NI 43-101 as he is the Vice President, Resources of Ivanhoe Mines. Mr. Gilchrist has verified the other technical data disclosed in this news release.

The stockpile grade estimates contained in this release are based upon bulk ore sampling from earlier underground headings, and vertical channel sample profiles from recent development. Bulk ore sampling was done on each heading every second blast and three 5-kilogram samples were taken. Since the beginning of October 2020, channel sample profiles are the primary data informing the stockpile grade estimates. These are cut approximately 15 metres apart in 1-metre vertical increments across the full vertical exposure using a handheld grinder, with a 100-to-150-gram sample collected. The samples are pulverized at the project’s onsite laboratory and analyzed using a portable XRF (pXRF) instrument. Kamoa Copper has routinely analyzed its exploration drill core for copper using pXRF, in addition to analysis at a commercial laboratory using four acid digest and ICP-OES. This data has demonstrated that pXRF results can be relied upon for grade control and run-of-mine sampling.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Project, which is available on the company’s website and under the company’s SEDAR profile at www.sedar.com:

- Kamoa-Kakula Integrated Development Plan 2020 dated October 13, 2020, prepared by OreWin Pty Ltd., China Nerin Engineering Co., Ltd., DRA Global, Epoch Resources, Golder Associates Africa, KGHM Cuprum R&D Centre Ltd., Outotec Oyj, Paterson and Cooke, Stantec Consulting International LLC, SRK Consulting Inc., and Wood plc.

The technical report includes relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Project cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal joint-venture projects in Southern Africa: the development of major new, mechanized, underground mines at the Kamoa-Kakula copper discoveries in the DRC and at the Platreef palladium-platinum-nickel-copper-rhodium-gold discovery in South Africa; and the extensive redevelopment and upgrading of the historic Kipushi zinc-copper-germanium-silver mine, also in the DRC.

Kamoa-Kakula is expected to begin producing copper in July 2021 and, through phased expansions, is positioned to become one of the world’s largest copper producers. Kamoa-Kakula and Kipushi will be powered by clean, renewable hydro-generated electricity and will be among the world’s lowest greenhouse gas emitters per unit of metal produced. Ivanhoe also is exploring for new copper discoveries on its wholly-owned Western Foreland exploration licences in the DRC, near the Kamoa-Kakula Project.

Information contacts

Investors: Bill Trenaman +1.604.331.9834 / Media: Matthew Keevil +1.604.558.1034

Forward-looking statements

Certain statements in this release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company, its projects, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results and speak only as of the date of this release.

Such statements include without limitation, the timing and results of: (i) statements regarding the Kamoa-Kakula Project is on track to have approximately three million tonnes of high-grade and medium-grade ore stockpiled on surface, containing more than 125,000 tonnes of copper, prior to the planned start of production in July 2021; (ii) statements regarding the Phase 1 concentrator plant remains on track to be mechanically complete in Q2 2021, with first copper concentrate production scheduled for July 202; (iii) statements that the risk of the risk of spreading or cross-contamination of COVID-19 at the Kamoa-Kakula Project is considered to be very low; (iv) statements regarding the expectation that Phase 2 of the project’s development when the Kakula concentrator processing capacity doubles to 7.6 Mtpa is to be commissioned in Q3 2022; (v) statements regarding Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated average feed grade of more than 6.0% copper over the first five years of operation; (vi) statements regarding Phases 1 and 2 combined are forecast to produce up to approximately 400,000 tonnes of copper per year; (vii) statements regarding based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes; (viii) statements regarding Kamoa-Kakula will be among the world’s lowest greenhouse gas emitters per unit of copper produced; (ix) statements regarding Kamoa-Kakula should have more than sufficient stockpiles ahead of the Phase 2 concentrator commissioning; (x) statements regarding approximately one half of the mine’s tailings will be sent back underground; (xi) statements regarding Kakula is expected to produce an extremely high grade and clean copper concentrate (containing over 55% copper and extremely low arsenic levels by world standards – approximately 0.01%) that will be highly coveted by copper smelters around the world; (xii) statements regarding the fully-refurbished Mwadingusha hydropower plant is expected to deliver approximately 78 megawatts of power to the national grid; (xiii) statements regarding energizing of Kakula’s main electrical substation and the concentrator plant by the end of March 2021; and (xiv) statements regarding long-term copper price sensitivities and the impact of project economics.

As well, all of the results of the Kakula definitive feasibility study, the Kakula-Kansoko pre-feasibility

study and the Kamoa-Kakula preliminary economic assessment, constitute forward-looking statements or information, and include future estimates of internal rates of return, net present value, future production, estimates of cash cost, proposed mining plans and methods, mine life estimates, cash flow forecasts, metal recoveries, estimates of capital and operating costs and the size and timing of phased development of the projects. Furthermore, with respect to this specific forward-looking information concerning the development of the Kamoa-Kakula Project, the company has based its assumptions and analysis on certain factors that are inherently uncertain. Uncertainties include: (i) the adequacy of infrastructure; (ii) geological characteristics; (iii) metallurgical characteristics of the mineralization; (iv) the ability to develop adequate processing capacity; (v) the price of copper; (vi) the availability of equipment and facilities necessary to complete development; (vii) the cost of consumables and mining and processing equipment; (viii) unforeseen technological and engineering problems; (ix) accidents or acts of sabotage or terrorism; (x) currency fluctuations; (xi) changes in regulations; (xii) the compliance by joint venture partners with terms of agreements; (xiii) the availability and productivity of skilled labour; (xiv) the regulation of the mining industry by various governmental agencies; (xv) the ability to raise sufficient capital to develop such projects; (xvi) changes in project scope or design; and (xvii) political factors.

Forward-looking statements and information involve significant risks and uncertainties, should not be read as guarantees of future performance or results and will not necessarily be accurate indicators of whether or not such results will be achieved. A number of factors could cause actual results to differ materially from the results discussed in the forward-looking statements or information, including, but not limited to, the factors discussed below and under “Risk Factors”, and elsewhere in this release, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

Although the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

The company’s actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors set forth below in the “Risk Factors” section in the company’s Q3 2020 MD&A and its current annual information form.

English

English Français

Français 日本語

日本語 中文

中文