Big Zinc Zone estimated to contain Measured and Indicated Mineral

Resources of 10.2 million tonnes at 34.89% zinc,

containing 7.8 billion pounds of zinc

In addition, adjacent zones contain copper-rich Measured

and Indicated Mineral Resources of 1.6 million tonnes

at 4.01% copper, containing 144 million pounds of copper

KIPUSHI, DEMOCRATIC REPUBLIC OF CONGO — Robert Friedland, Executive Chairman of Ivanhoe Mines (TSX: IVN), and Lars-Eric Johansson, Chief Executive Officer, today announced the receipt of a new, independent, Mineral Resource estimate for the company’s historic, high-grade, Kipushi zinc-copper-germanium-lead-silver mine. Kipushi is a joint venture between Ivanhoe Mines and Gécamines, the state-owned mining company.

Highlights of this initial estimate, prepared by the MSA Group, of Johannesburg, South Africa, in compliance with CIM definition standards, are:

- Measured and Indicated Mineral Resources in the Big Zinc Zone of 10.2 million tonnes at grades of 34.89% zinc, 0.65% copper, 19 grams per tonne (g/t) silver and 51 g/t germanium, at a 7% zinc cut-off, containing an estimated 7.8 billion pounds of zinc.

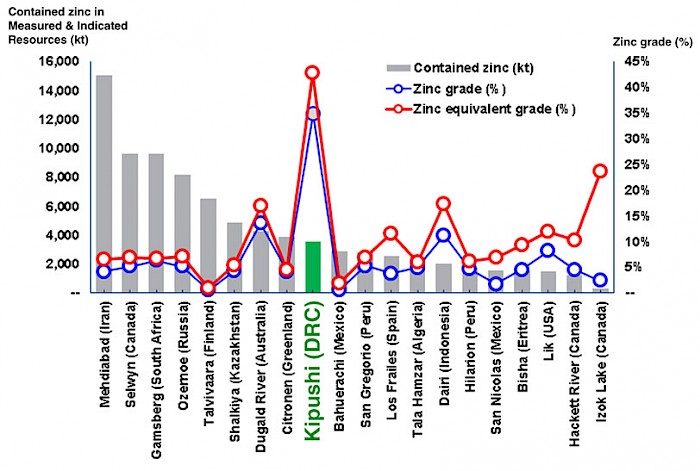

- The zinc grade of Kipushi’s Measured and Indicated Mineral Resources in the Big Zinc Zone is more than twice as high as the world’s next-highest-grade zinc project, independently ranked by Wood Mackenzie, an international industry research and consulting group, based on contained zinc (Figure 1).

- Zinc-rich Inferred Mineral Resources total an additional 1.9 million tonnes at grades of 28.24% zinc, 1.18% copper, 10 g/t silver and 53 g/t germanium. The Inferred Mineral Resources are contained partially in the Big Zinc Zone and partially in the Southern Zinc Zone.

- Kipushi’s copper-rich Measured and Indicated Mineral Resources contained in the adjacent Fault Zone, Fault Zone Splay and Série Récurrente Zone total an additional 1.63 million tonnes at grades of 4.01% copper, 2.87% zinc and 22 g/t silver, at a 1.5% copper cut-off, containing 144 million pounds of copper.Copper-rich Inferred Mineral Resources in these zones total an additional 1.64 million tonnes at grades of 3.30% copper, 6.97% zinc and 19 g/t silver.

- Ivanhoe’s exploration program has demonstrated that zinc and copper mineralization of the Kipushi system remains open laterally and at depth.Results recently received from hole KPU081, drilled on section line 6S, confirm high-grade copper-zinc mineralization at depth. KPU081 intersected 60.5 metres (21.7 metres true thickness) grading 2.6% copper, 36.2% zinc, 19 g/t silver and 204 g/t germanium to a depth of 1,763 metres. Included in this interval was an intersection from 580.9 metres to 591.3 metres (3.8 metres true thickness) grading 56.3% zinc, 0.5% copper, 12 g/t silver and 397 g/t germanium.

“This independent estimate of Kipushi’s Mineral Resources has exceeded our expectations. We are convinced that significant additional Mineral Resources can be delineated at Kipushi,” said Mr. Friedland.

“With a current resource now established, we are evaluating technical and infrastructure options to best advance the project. The exceptionally high grades that consistently are being discovered at Kipushi are unique in the international mining industry and provide further confirmation that this project has the potential to benefit the people of the Democratic Republic of Congo for decades to come when it returns to production.”

The Kipushi Mine is on the Central African Copperbelt in the Democratic Republic of Congo’s (DRC) southern Haut-Katanga province, one of Africa’s major mining hubs. The mine, which began operations in 1924, is located approximately 30 kilometres southwest of the provincial capital, Lubumbashi, and less than one kilometre from the DRC-Zambia border. Ivanhoe holds a 68% interest in Kipushi and the state-owned mining company, Gécamines, holds the remaining 32% interest.

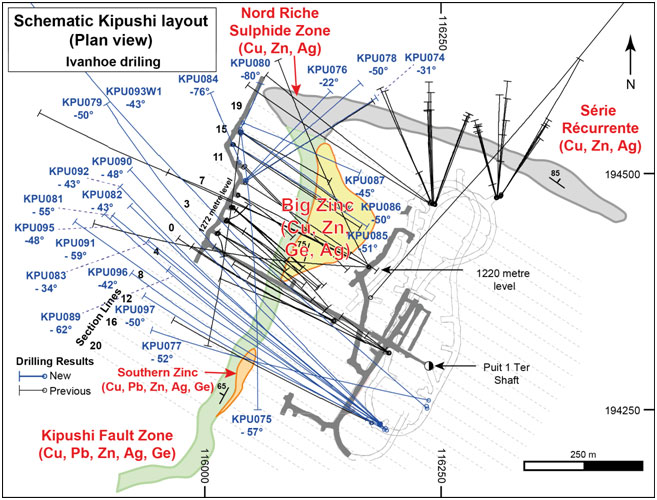

The mineralization at Kipushi comprises sulphide replacement bodies within the Kakontwe Sub-Group dolomites and Série Récurrente Sub-Group dolomitic shales of the Nguba Group. Two zones of zinc-rich mineralization occur (the Big Zinc Zone and the Southern Zinc Zone) adjacent to the copper-rich Fault Zone mineralization. The Fault Zone strikes north-northeast to south-southwest and dips approximately 70° to the west. The Big Zinc forms an irregular, steeply-dipping pipe-like body in the immediate footwall to the Fault Zone, the Southern Zinc runs along the footwall of the Fault Zone between -1,150-metre and -1,300-metre levels. A second zone of copper-rich mineralization occurs in the Série Récurrente, which strikes from east to west, is sub-vertical and plunges steeply to the west. Where the Fault Zone and Série Récurrente meet, mineralization tends to be enhanced in a sub-zone known as the Nord Riche. A sub-vertical, copper-zinc-germanium-rich sulphide zone occurs as a splay from the Fault Zone at depth toward the southwest, and has been named the Fault Zone Splay. Significant concentrations of lead, silver, cobalt and germanium occur in variable amounts in all zones.

Germanium is a high-tech metal used in light-emitting diodes (LED), fibre-optic networks, infrared night vision systems and solar cell applications. The metal currently is trading at approximately US$1,200 a kilogram.

The new Mineral Resource estimate was prepared in accordance with the 2014 CIM definition standards, incorporated by reference into Canadian National Instrument 43-101 – Standards of Disclosure for Mineral Projects. Ivanhoe is preparing a NI 43-101-compliant Preliminary Economic Assessment for Kipushi.

The MSA Mineral Resource estimate was based on the results of 84 drill holes completed at Kipushi by Ivanhoe Mines and an additional 107 historical holes drilled by Gécamines. Mineral Resource estimates were completed below the -1,150-metre-level on the Big Zinc Zone, Southern Zinc Zone, Fault Zone and Série Récurrente Zone. The Mineral Resources were categorized either as zinc-rich resources or copper-rich resources, depending on the most abundant metal. The Big Zinc and Southern Zinc zones have been tabulated using zinc cut-offs and are shown in Table 1; the Fault Zone, the Fault Zone Splay and Série Récurrente Zone have been tabulated using copper cut-offs and are shown in Table 2.

For the zinc-rich zones, the Mineral Resource is reported at a base-case cut-off grade of 7.0% zinc and the copper-rich zones at a base-case cut-off grade of 1.5% copper. Given the considerable revenue that could be obtained from the additional metals in each zone, MSA considers that mineralization at these cut-off grades will satisfy reasonable prospects for economic extraction.

Figure 1: Top 20 zinc projects by contained zinc.

Source: Wood Mackenzie. Note: All tonnes and metal grades of individual metals used in the equivalency calculation of the above mentioned projects (except for Kipushi) are based on public disclosure and have been compiled by Wood Mackenzie. All metal grades have been converted by Wood Mackenzie to a zinc equivalent grade at price assumptions of US$1.01/lb zinc, US$2.86/lb copper, US$0.91/lb lead, US$12.37/lb cobalt, US$1,201/oz gold, US$17/oz silver and US$2,000/kg germanium.

| Table 1: Kipushi Zinc-Rich Mineral Resource at 7% Zn Cut-Off Grade, 23 January 2016 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Zone | Category | Tonnes (Millions) |

Zn % |

Cu % |

Pb % |

Ag g/t |

Co ppm |

Ge g/t |

| Big Zinc | Measured | 3.59 | 38.39 | 0.67 | 0.36 | 18 | 17 | 54 |

| Indicated | 6.60 | 32.99 | 0.63 | 1.29 | 20 | 14 | 50 | |

| Inferred | 0.98 | 36.96 | 0.79 | 0.14 | 7 | 16 | 62 | |

| Southern Zinc Zone | Indicated | 0.00 | – | – | – | – | – | – |

| Inferred | 0.89 | 18.70 | 1.61 | 1.70 | 13 | 15 | 43 | |

| Total | Measured | 3.59 | 38.39 | 0.67 | 0.36 | 18 | 17 | 54 |

| Indicated | 6.60 | 32.99 | 0.63 | 1.29 | 20 | 14 | 50 | |

| Measured & Indicated | 10.18 | 34.89 | 0.65 | 0.96 | 19 | 15 | 51 | |

| Inferred | 1.87 | 28.24 | 1.18 | 0.88 | 10 | 15 | 53 | |

| Contained Metal Quantities | ||||||||

| Zone | Category | Tonnes | Zn Pounds | Cu Pounds | Pb Pounds | Ag Ounces | Co Pounds | Ge Ounces |

| (Millions) | (Millions) | (Millions) | (Millions) | (Millions) | (Millions) | (Millions) | ||

| Big Zinc | Measured | 3.59 | 3035.8 | 53.1 | 28.7 | 2.08 | 0.13 | 6.18 |

| Indicated | 6.60 | 4797.4 | 91.9 | 187.7 | 4.15 | 0.20 | 10.54 | |

| Inferred | 0.98 | 797.2 | 17.1 | 3.0 | 0.23 | 0.03 | 1.96 | |

| Southern Zinc Zone | Indicated | 0.00 | 0.0 | 0.0 | 0.0 | 0.00 | 0.00 | 0.00 |

| Inferred | 0.89 | 368.6 | 31.8 | 33.5 | 0.38 | 0.03 | 1.23 | |

| Total | Measured | 3.59 | 3035.8 | 53.1 | 28.7 | 2.08 | 0.13 | 6.18 |

| Indicated | 6.60 | 4797.4 | 91.9 | 187.7 | 4.15 | 0.20 | 10.54 | |

| Measured & Indicated | 10.18 | 7833.3 | 144.9 | 216.4 | 6.22 | 0.33 | 16.71 | |

| Inferred | 1.87 | 1168.7 | 49.6 | 36.8 | 0.61 | 0.06 | 3.21 | |

Notes:

- All tabulated data has been rounded and as a result minor computational errors may occur.

- Mineral Resources which are not Mineral Reserves have no demonstrated economic viability.

- The Mineral Resource is reported as the total in-situ Mineral Resource.

- Metal quantities are reported in multiples of Troy Ounces or Avoirdupois Pounds.

- The cut-off grade calculation was based on the following assumptions: zinc price of 1.02 USD/lb, mining cost of 50 USD/tonne, processing cost of 10 USD/tonne, G&A and holding cost of 10 USD/tonne, transport of 55% Zn concentrate at 375 USD/tonne, 90% zinc recovery and 85% payable zinc.

| Table 2: Kipushi Copper-Rich Mineral Resource at 1.5% Cu Cut-Off Grade, 23 January 2016 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Zone | Category | Tonnes | Cu | Zn | Pb | Ag | Co | Ge |

| (Millions) | % | % | % | g/t | ppm | g/t | ||

| Fault Zone | Measured | 0.14 | 2.78 | 1.25 | 0.05 | 19 | 107 | 20 |

| Indicated | 1.01 | 4.17 | 2.64 | 0.09 | 23 | 216 | 20 | |

| Inferred | 0.94 | 2.94 | 5.81 | 0.18 | 22 | 112 | 26 | |

| Série Récurrente |

Indicated | 0.48 | 4.01 | 3.82 | 0.02 | 21 | 56 | 6 |

| Inferred | 0.34 | 2.57 | 1.02 | 0.06 | 8 | 29 | 1 | |

| Fault Zone Splay |

Inferred | 0.35 | 4.99 | 15.81 | 0.005 | 20 | 127 | 81 |

| Total | Measured | 0.14 | 2.78 | 1.25 | 0.05 | 19 | 107 | 20 |

| Indicated | 1.49 | 4.12 | 3.02 | 0.07 | 22 | 165 | 15 | |

| Measured & Indicated |

1.63 | 4.01 | 2.87 | 0.06 | 22 | 160 | 16 | |

| Inferred | 1.64 | 3.30 | 6.97 | 0.12 | 19 | 98 | 33 | |

| Contained Metal Quantities | ||||||||

| Zone | Category | Tonnes | Cu Pounds |

Zn Pounds |

Pb Pounds |

Ag Ounces |

Co Pounds |

Ge Ounces |

| (Millions) | (Millions) | (Millions) | (Millions) | (Millions) | (Millions) | (Millions) | ||

| Fault Zone | Measured | 0.14 | 8.5 | 3.8 | 0.2 | 0.09 | 0.03 | 0.09 |

| Indicated | 1.01 | 93.2 | 59.1 | 1.9 | 0.75 | 0.48 | 0.64 | |

| Inferred | 0.94 | 61.1 | 120.9 | 3.8 | 0.68 | 0.23 | 0.79 | |

| Série Récurrente |

Indicated | 0.48 | 42.4 | 40.5 | 0.2 | 0.32 | 0.06 | 0.09 |

| Inferred | 0.34 | 19.4 | 7.7 | 0.4 | 0.09 | 0.02 | 0.01 | |

| Fault Zone Splay |

Inferred | 0.35 | 38.9 | 123.3 | 0.0 | 0.23 | 0.10 | 0.92 |

| Total | Measured | 0.14 | 8.5 | 3.8 | 0.2 | 0.09 | 0.03 | 0.09 |

| Indicated | 1.49 | 135.7 | 99.6 | 2.1 | 1.08 | 0.54 | 0.73 | |

| Measured & Indicated |

1.63 | 144.1 | 103.4 | 2.3 | 1.16 | 0.58 | 0.82 | |

| Inferred | 1.64 | 119.4 | 251.8 | 4.3 | 1.00 | 0.35 | 1.73 | |

Notes:

- All tabulated data has been rounded and as a result minor computational errors may occur.

- Mineral Resources which are not Mineral Reserves have no demonstrated economic viability.

- The Mineral Resource is reported as the total in-situ Mineral Resource.

- Metal quantities are reported in multiples of Troy Ounces or Avoirdupois Pounds.

- The cut-off grade calculation was based on the following assumptions: copper price of 2.97 USD/lb, mining cost of 50 USD/tonne, processing cost of 10 USD/tonne, G&A and holding cost of 10 USD/tonne, 90% copper recovery and 96% payable copper.

To demonstrate the sensitivity of the resources to cut-off grade, MSA tabulated the zinc-rich zones using a number of cut-off grades as shown in Table 3 (Measured and Indicated) and Table 4 (Inferred) respectively.

| Table 3: Kipushi Zinc-Rich Bodies Measured and Indicated Mineral Resource Grade Tonnage, 23 January 2016 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cut Off | Tonnes | Zn | Contained Zn Pounds |

Cu | Pb | Ag | Co | Ge |

| Zn% | (Millions) | % | (Millions) | % | % | g/t | ppm | g/t |

| 5 | 10.46 | 34.12 | 7870.0 | 0.65 | 0.95 | 19 | 15 | 50 |

| 7 | 10.18 | 34.89 | 7833.3 | 0.65 | 0.96 | 19 | 15 | 51 |

| 10 | 9.78 | 35.99 | 7757.4 | 0.63 | 0.98 | 19 | 15 | 52 |

| 12 | 9.50 | 36.72 | 7689.4 | 0.62 | 1.00 | 19 | 15 | 53 |

| 15 | 9.06 | 37.85 | 7559.1 | 0.59 | 1.01 | 20 | 15 | 54 |

Notes:

- All tabulated data has been rounded and as a result minor computational errors may occur.

- Mineral Resources which are not Mineral Reserves have no demonstrated economic viability.

- The Mineral Resource is reported as the total in-situ Mineral Resource.

- Metal quantities are reported in multiples of Troy Ounces or Avoirdupois Pounds.

| Table 4: Kipushi Zinc-Rich Bodies Inferred Mineral Resource Grade Tonnage, 23 January 2016 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cut Off | Tonnes | Zn | Contained Zn Pounds |

Cu | Pb | Ag | Co | Ge |

| Zn% | (Millions) | % | (Millions) | % | % | g/t | ppm | g/t |

| 5 | 1.89 | 27.98 | 1168.8 | 1.19 | 0.88 | 10 | 15 | 53 |

| 7 | 1.87 | 28.24 | 1165.7 | 1.18 | 0.88 | 10 | 15 | 53 |

| 10 | 1.82 | 28.85 | 1154.8 | 1.17 | 0.88 | 10 | 15 | 54 |

| 12 | 1.75 | 29.47 | 1139.8 | 1.15 | 0.87 | 10 | 15 | 55 |

| 15 | 1.56 | 31.42 | 1082.1 | 1.08 | 0.83 | 10 | 15 | 57 |

Notes:

- All tabulated data has been rounded and as a result minor computational errors may occur.

- Mineral Resources which are not Mineral Reserves have no demonstrated economic viability.

- The Mineral Resource is reported as the total in-situ Mineral Resource.

- Metal quantities are reported in multiples of Troy Ounces or Avoirdupois Pounds.

The Measured and Indicated and Inferred Mineral Resource for the copper-rich bodies has been tabulated using a number of cut-off grades as shown in Tables 5 and 6 respectively.

| Table 5: Kipushi Copper-Rich Bodies Measured and Indicated Mineral Resource Grade Tonnage, 23 January 2016 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cut Off | Tonnes | Cu | Contained Cu Pounds |

Zn | Pb | Ag | Co | Ge | |

| Cu% | (Millions) | % | (Millions) | % | % | g/t | ppm | g/t | |

| 1.0 | 2.56 | 3.00 | 169.2 | 2.01 | 0.05 | 17 | 114 | 11 | |

| 1.5 | 1.63 | 4.01 | 144.1 | 2.87 | 0.06 | 22 | 160 | 16 | |

| 2.0 | 1.17 | 4.92 | 126.6 | 3.66 | 0.08 | 26 | 202 | 19 | |

| 2.5 | 0.95 | 5.54 | 115.8 | 4.06 | 0.08 | 29 | 227 | 20 | |

| 3.0 | 0.82 | 5.99 | 108.0 | 4.32 | 0.08 | 30 | 244 | 20 | |

Notes:

- All tabulated data has been rounded and as a result minor computational errors may occur.

- Mineral Resources which are not Mineral Reserves have no demonstrated economic viability.

- The Mineral Resource is reported as the total in-situ Mineral Resource.

- Metal quantities are reported in multiples of Troy Ounces or Avoirdupois Pounds.

| Table 6: Kipushi Copper-Rich Bodies Inferred Mineral Resource Grade Tonnage, 23 January 2016 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cut Off | Tonnes | Cu | Contained Cu Pounds |

Zn | Pb | Ag | Co | Ge |

| Cu% | (Millions) | % | (Millions) | % | % | g/t | ppm | g/t |

| 1.0 | 2.40 | 2.64 | 139.8 | 5.85 | 0.09 | 16 | 79 | 29 |

| 1.5 | 1.64 | 3.30 | 119.4 | 6.97 | 0.12 | 19 | 98 | 33 |

| 2.0 | 1.24 | 3.81 | 104.2 | 7.29 | 0.13 | 20 | 109 | 33 |

| 2.5 | 0.90 | 4.40 | 87.6 | 8.01 | 0.13 | 21 | 113 | 34 |

| 3.0 | 0.68 | 4.95 | 74.0 | 8.38 | 0.15 | 21 | 118 | 34 |

Notes:

- All tabulated data has been rounded and as a result minor computational errors may occur.

- Mineral Resources which are not Mineral Reserves have no demonstrated economic viability.

- The Mineral Resource is reported as the total in-situ Mineral Resource.

- Metal quantities are reported in multiples of Troy Ounces or Avoirdupois Pounds.

The Mineral Resource has been declared from approximately 1,150 metres below surface, extensive mining having historically taken place in the levels above. Although exploration potential, including pillars and remnants, exists above the -1,150-metre level, this has not been closely examined during the current phase of exploration activity and was not included in the model for reporting of the Mineral Resource. The maximum depth of the Mineral Resource of 1,810 metres below surface is dictated by the extent of drilling. The Mineral Resource plunges toward the DRC-Zambia border and therefore has been constrained to the area considered to be within the DRC.

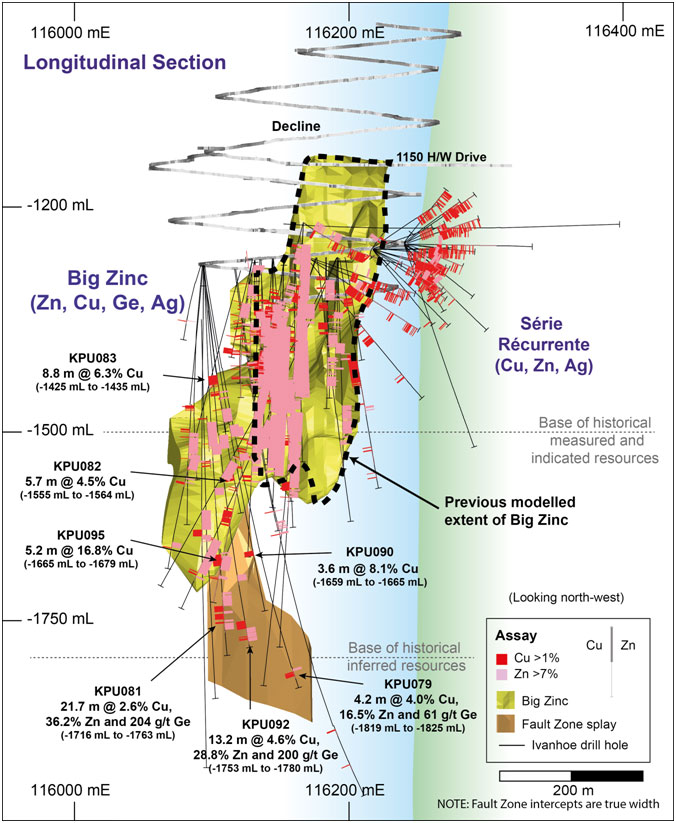

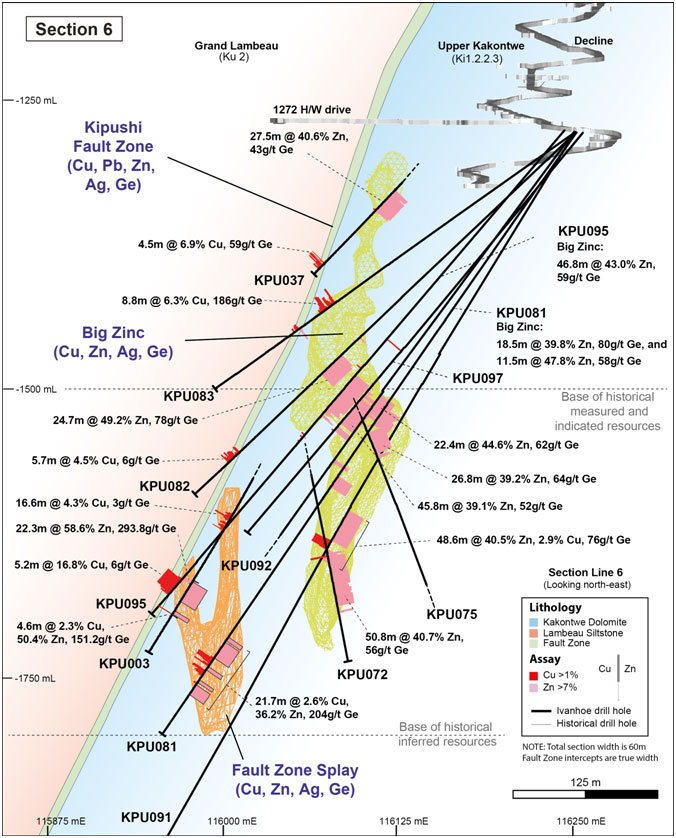

Final drill results from underground exploration confirm expansion of the Big Zinc Zone and Fault Zone and demonstrate that the mineralized zones are still open.

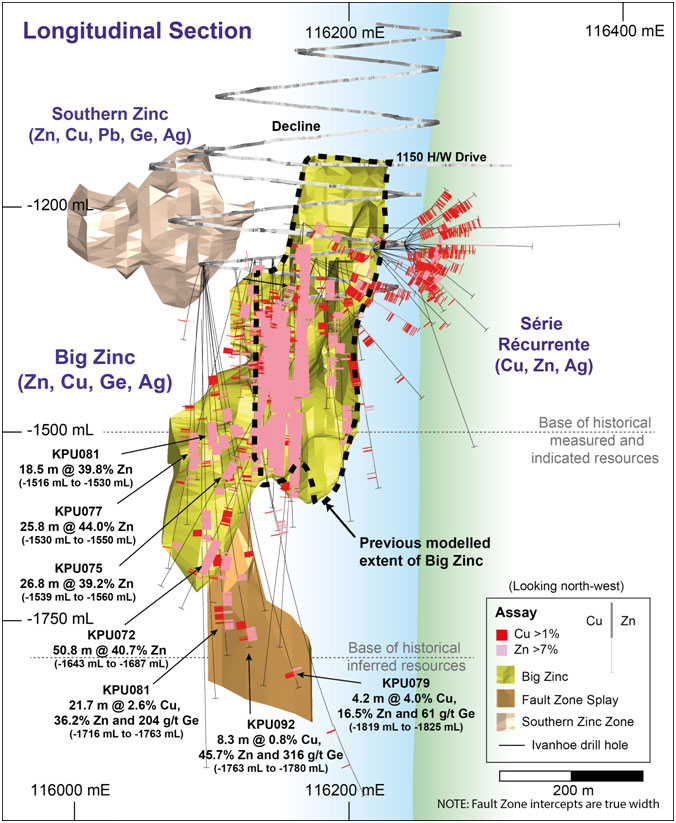

Additional exploration drilling in the southern extension area sucessfully confirmed that both the Big Zinc Zone and Fault Zone remain open at depth and to the south with significant intersections on both structures in recent drilling. Additional high-grade copper-zinc-germanium mineralization also was discovered in the Fault Zone and in Fault Zone Splay in the immediate footwall of the Fault Zone. The new assay results and the interpretation of the connectivity of the zones with the main Big Zinc body are shown in Figures 4, 5 and 6. The disclosed results were included in the database used for the resource estimate. Highlights of the drilling included:

- KPU079 drilled on section line 6S intersected 11.8 metres of mixed massive sulphide, (4.2 metres true thickness) grading 4.0% copper, 16.5% zinc, 6 g/t silver and 61 g/t germanium. At 1,825 metres below surface this remains the deepest intersection to date from the Kipushi Project.

- KPU081 drilled on section line 6S intersected Big Zinc sphalerite from 289.6 metres to 308.1 metres grading 39.8% zinc, 0.3% copper and 80 g/t germanium and from 361.8 metres to 373.2 metres grading 47.8% zinc, 0.2% copper and 58 g/t germanium. The hole continued to a Fault Zone Splay intersection of 60.5 metres (21.7 metres true thickness) grading 2.6% copper, 36.2% zinc, 19 g/t silver and 204 g/t germanium to a depth of 1,763 metres. Included in this interval was an intersection from 580.9 metres to 591.3 metres (3.8 metres true thickness) grading 56.3% zinc, 0.5% copper, 12 g/t silver and 397 g/t germanium.

- KPU095 drilled on section line 6S intersected 46.8 metres of Big Zinc massive sphalerite grading 43.0% zinc, 0.4% copper and 59 g/t germanium. A second Fault Zone interval intersected 21.9 metres (6.0 metres true thickness) of massive chalcopyrite grading 14.5% copper, 7.0% zinc and 58 g/t silver.

Table 7: Summary of recent assay results by Ivanhoe Mines at Kipushi (part 1).

| BHID | Line | Dip to BRG | Area | From (m) |

To (m) |

Length (m) |

True Width (m) |

Au g/t |

Ag g/t |

Co ppm |

Cu % |

Ge g/t |

Zn % |

S % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KPU074 | 11N-29N | -31 to 055 | FZ-NR | 71.3 | 96.0 | 24.7 | 22.6 | 0.0 | 20 | 818 | 9.1 | 8 | 7.6 | 14 |

| 105.9 | 109.0 | 3.1 | 2.8 | 0.0 | 24 | 80 | 9.6 | 5 | 0.2 | 10 | ||||

| KPU075 | N-S | -57 to 172 | BZ | 325.6 | 352.4 | 26.8 | – | 0.0 | 4 | 2 | 0.2 | 64 | 39.2 | 34 |

| KPU076 | 11N-29N | -22 to 043 | FZ-NR | 82.0 | 87.0 | 5.1 | 2.0 | 0.0 | 5 | 216 | 2.4 | 0 | 0.0 | 3 |

| 90.4 | 94.0 | 3.6 | 1.4 | 0.0 | 6 | 0 | 2.5 | 0 | 0.0 | 3 | ||||

| KPU077 | 0S-12S | -52 to 282 | BZ | 309.2 | 334.9 | 25.8 | – | 0.0 | 6 | 1 | 0.2 | 54 | 44.0 | 33 |

| 355.6 | 360.4 | 4.8 | – | 0.1 | 24 | 166 | 5.8 | 12 | 5.4 | 26 | ||||

| 456.7 | 465.1 | 8.5 | – | 0.0 | 2 | 3 | 0.2 | 63 | 37.4 | 22 | ||||

| KPU078 | 11N-29N | -52 to 053 | FZ-NR | 136.0 | 140.0 | 4.0 | 1.9 | 0.0 | 14 | 0 | 3.7 | 0 | 0.1 | 4 |

| KPU079 | 6S-5N | -51 to 317 | BZ | 278.8 | 293.5 | 14.7 | – | 0.0 | 10 | 3 | 0.3 | 78 | 47.0 | 35 |

| 323.1 | 334.5 | 11.3 | – | 0.0 | 4 | 2 | 0.1 | 44 | 43.4 | 35 | ||||

| FZS | 688.1 | 699.9 | 11.8 | 4.2 | 0.0 | 6 | 250 | 4.0 | 61 | 16.5 | 31 | |||

| including | 688.1 | 691.5 | 3.4 | 1.2 | 0.0 | 2 | 7 | 0.2 | 175 | 56.1 | 32 | |||

| including | 691.9 | 699.9 | 8.0 | 2.9 | 0.1 | 8 | 364 | 5.7 | 15 | 0.4 | 31 | |||

| KPU080 | 17N-21N | -81 to 024 | FZ-NR | 132.0 | 135.2 | 3.2 | 1.7 | 0.0 | 11 | 8 | 2.2 | 0 | 0.1 | 2 |

| 140.0 | 158.6 | 18.6 | 10.1 | 0.0 | 26 | 28 | 5.7 | 2 | 0.1 | 6 | ||||

| 162.0 | 168.0 | 6.0 | – | 0.0 | 16 | 5 | 3.6 | 6 | 0.0 | 4 | ||||

| KPU081 | 6S-4S | -55 to 305 | BZ | 289.6 | 308.1 | 18.5 | – | 0.0 | 11 | 0 | 0.3 | 80 | 39.8 | 36 |

| 361.8 | 373.2 | 11.5 | – | 0.0 | 6 | 5 | 0.2 | 58 | 47.8 | 36 | ||||

| FZS | 530.9 | 591.4 | 60.5 | 21.7 | 0.0 | 19 | 65 | 2.6 | 204 | 36.2 | 31 | |||

| FZS | 552.9 | 572.0 | 19.1 | 6.8 | 0.0 | 34 | 128 | 6.9 | 28 | 10.4 | 29 | |||

| FZS | 580.9 | 591.4 | 10.5 | 3.8 | 0.0 | 12 | 17 | 0.5 | 397 | 56.3 | 32 | |||

| KPU082 | 6S-4S | -43 to 313 | BZ | 258.0 | 261.0 | 3.0 | – | 0.0 | 1 | 0 | 0.1 | 20 | 11.9 | 7 |

| 280.1 | 304.8 | 24.7 | – | 0.0 | 8 | 1 | 0.2 | 78 | 49.2 | 34 | ||||

| FZ-EX | 403.0 | 416.9 | 13.9 | 5.7 | 0.0 | 15 | 191 | 4.5 | 6 | 0.2 | 10 | |||

| KPU083 | 4S | -34 to 307 | FZ-EX | 254.6 | 270.8 | 16.2 | 8.8 | 0.0 | 28 | 0 | 6.3 | 186 | 0.1 | 8 |

| 291.3 | 299.1 | 7.8 | 4.3 | 0.0 | 21 | 122 | 2.3 | 25 | 8.2 | 24 | ||||

| KPU084 | 17-19N | -78 to 340 | FZ-NR | 251.0 | 256.4 | 5.4 | 1.3 | 0.0 | 10 | 0 | 0.0 | 2 | 16.8 | 17 |

| KPU085 | 15N | -49 to 121 | FZ | 83.7 | 91.2 | 7.5 | 6.7 | 0.0 | 19 | 367 | 4.9 | 6 | 0.1 | 7 |

| BZ | 134.0 | 160.6 | 26.6 | 0.0 | 78 | 35 | 1.0 | 35 | 35.5 | 25 | ||||

| 134.0 | 137.5 | 3.5 | 0.0 | 151 | 250 | 6.8 | 41 | 18.7 | 20 | |||||

| 181.2 | 186.6 | 5.5 | 0.0 | 3 | 0 | 0.1 | 52 | 34.5 | 20 | |||||

| KPU086 | 17N | -51 to 124 | FZ | No Significant Intercept | ||||||||||

| BZ | 147.2 | 164.4 | 17.2 | 0.0 | 90 | 4 | 0.3 | 30 | 38.8 | 29 | ||||

| 189.4 | 192.1 | 2.7 | 0.0 | 9 | 0 | 0.2 | 34 | 23.8 | 26 | |||||

| KPU087 | 19N | -45 to 112 | FZ-NR | 75.6 | 87.0 | 11.4 | 10.6 | 0.0 | 26 | 12 | 5.4 | 1 | 0.5 | 6 |

| 75.6 | 81.6 | 6.0 | 5.5 | 0.0 | 37 | 22 | 7.8 | 3 | 0.4 | 9 | ||||

Note: Kipushi FZ = Kipushi Fault Zone; NR = Nord Riche, BZ = Big Zinc, FZS = Splay of Fault Zone at depth. True thickness not calculated for irregular replacement mineralized zones.

Table 8: Summary of recent assay results by Ivanhoe Mines at Kipushi (part 2).

| BHID | Line | Dip to BRG | Area | From (m) |

To (m) |

Length (m) |

True Width (m) |

Au g/t |

Ag g/t |

Co ppm |

Cu % |

Ge g/t |

Zn % |

S % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KPU088 | 6S | 0 | abandoned | |||||||||||

| KPU089 | 6S | -62 to 303 | No Significant Intercept | |||||||||||

| KPU090 | 1N | -48 to 313 | BZ | 283.5 | 303.3 | 19.8 | – | 0.0 | 8 | 0 | 0.4 | 43 | 47.0 | 37 |

| FZS | 500.1 | 508.6 | 8.5 | 3.6 | 0.0 | 42 | 148 | 8.1 | 0 | 0.1 | 35 | |||

| KPU091 | 6S | -59 to 301 | BZ | 381.8 | 430.4 | 48.6 | – | 0.1 | 11 | 56 | 2.9 | 76 | 40.5 | 35 |

| including | 381.8 | 412.1 | 30.3 | – | 0.0 | 7 | 9 | 0.1 | 100 | 51.1 | 34 | |||

| BZ | 412.1 | 420.2 | 8.1 | – | 0.1 | 35 | 299 | 15.8 | 6 | 0.4 | 35 | |||

| BZ | 420.2 | 430.4 | 10.2 | – | 0.0 | 6 | 5 | 0.9 | 57 | 38.7 | 37 | |||

| KPU092 | 2N | -53 to 207 | BZ | 283.6 | 306.0 | 22.4 | – | 0.0 | 7 | 1 | 0.2 | 62 | 44.6 | 34 |

| BZ | 352.1 | 356.5 | 4.4 | – | 0.0 | 3 | 2 | 0.1 | 48 | 38.0 | 28 | |||

| FZS | 514.4 | 524.0 | 9.6 | 3.7 | 0.0 | 15 | 19 | 0.3 | 262 | 58.9 | 32 | |||

| 589.2 | 623.0 | 33.8 | 13.2 | 0.0 | 19 | 240 | 4.6 | 200 | 28.8 | 30 | ||||

| including | 589.2 | 600.0 | 10.8 | 4.2 | 0.0 | 32 | 667 | 12.5 | 1 | 0.2 | 30 | |||

| 601.7 | 623.0 | 21.3 | 8.3 | 0.0 | 13 | 32 | 0.8 | 316 | 45.7 | 30 | ||||

| KPU093 | 0-29N | -43 to 311 | 178.0 | 181.0 | 3.0 | – | 0.0 | 0 | 0 | 0.1 | 173 | 24.3 | 14 | |

| 206.8 | 210.3 | 3.6 | – | 0.1 | 6 | 0 | 0.3 | 62 | 25.5 | 25 | ||||

| 218.0 | 234.4 | 16.4 | – | 0.0 | 4 | 0 | 0.2 | 78 | 33.3 | 30 | ||||

| 257.0 | 261.7 | 4.7 | – | 0.0 | 4 | 0 | 0.2 | 77 | 41.7 | 28 | ||||

| KPU093 | 0-29N | -43 to 311 | BZ | 304.0 | 338.5 | 34.5 | – | 0.0 | 9 | 6 | 0.2 | 39 | 45.8 | 34 |

| 379.7 | 383.0 | 3.3 | – | 0.0 | 4 | 6 | 0.3 | 192 | 40.4 | 21 | ||||

| 452.4 | 455.0 | 2.6 | – | 0.0 | 13 | 154 | 4.3 | 57 | 15.8 | 21 | ||||

| 473.0 | 482.4 | 9.4 | – | 0.0 | 12 | 6 | 0.1 | 75 | 28.5 | 16 | ||||

| KPU093W1 | 0-29N | -43to311 | BZ | 492.0 | 495.1 | 3.1 | – | 0.0 | 6 | 23 | 0.5 | 24 | 46.3 | 29 |

| KPU094 | 10S | -22 to 296 | FZ-FZS | 192.9 | 196.3 | 3.3 | 2.4 | 0.0 | 5 | 15 | 0.4 | 13 | 5.7 | 6 |

| KPU095 | 6S | -48 to 302 | BZ | 278.0 | 324.8 | 46.8 | – | 0.0 | 8 | 7 | 0.4 | 59 | 43.0 | 33 |

| FZ | 507.9 | 529.7 | 21.9 | 6.0 | 0.0 | 58 | 53 | 14.5 | 9 | 7.0 | 32 | |||

| including | 511.0 | 529.7 | 18.7 | 5.2 | 0.1 | 67 | 61 | 16.8 | 6 | 1.8 | 32 | |||

| KPU096 | 8S | -42 to 297 | BZ | 388.1 | 391.1 | 2.9 | – | 0.0 | 10 | 0 | 0.3 | 27 | 34.2 | 36 |

| FZ | 398.6 | 402.0 | 3.4 | 1.3 | 0.0 | 12 | 19 | 1.8 | 46 | 0.2 | 13 | |||

| KPU097 | 10S | -50 to 298 | BZ | 291.6 | 337.4 | 45.8 | – | 0.0 | 9 | 13 | 0.3 | 52 | 39.1 | 33 |

| including | 291.6 | 328.5 | 36.8 | – | 0.0 | 8 | 11 | 0.2 | 56 | 43.2 | 35 | |||

Note: FZ=Kipushi Fault Zone; NR = Nord Riche, BZ = Big Zinc, FZS = Splay off Fault Zone at depth. True thickness not calculated for irregular replacement mineralized zones.

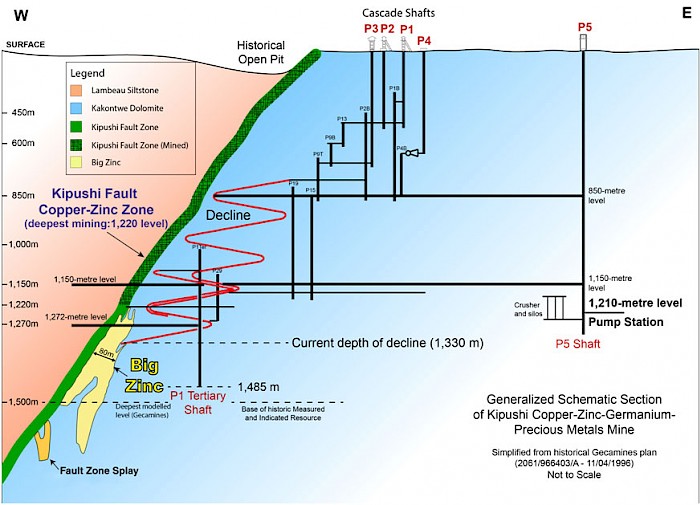

Figure 2: Schematic Kipushi cross-section showing mine infrastructure, the Big Zinc and Kipushi Fault zones.

Figure 3: Plan of the 1,272-metre level with drill sections, showing schematically the location of the mineralized zones and infrastructure in the Cascades side of the mine. The Big Zinc is interpreted to plunge steeply to the southwest.

Figure 4: Schematic showing Big Zinc Mineral Resource outline and recent Big Zinc and Fault Zone Splay intercepts in drill holes KPU079 and KPU081.

Figure 5: Schematic longitudinal section looking northwest, showing Big Zinc Mineral Resource outline and Fault Zone and Fault Zone Splay copper intercepts in recent drill holes.

Figure 6: Section Line 6S looking northeast, showing new intersections of copper and zinc mineralization.

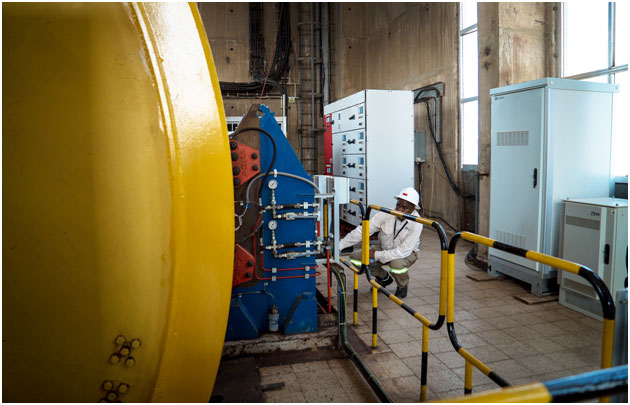

Main underground pumping station being re-established at 1,210-metre level

In December 2015, Ivanhoe achieved a major milestone in its upgrading of Kipushi’s underground infrastructure when the water level in Shaft 5 was pumped below the mine’s main pumping station situated at 1,210 metres underground.

Mr. Friedland noted that since Ivanhoe assumed responsibility at Kipushi, significant progress has been made in rehabilitating the surface and underground infrastructure at Kipushi. The dewatering program, implemented by Ivanhoe in late 2011, has been successful and the water levels are now being maintained below Kipushi’s main pumping station on the 1,210-metre level. Three new, high-capacity Grifo pumps have been purchased and will be installed at the main pumping station alongside the five existing high-capacity Sulzer pumps that are being refurbished. The expected cost of the upgrade and refurbishment of the main pumping station is expected to be approximately US$3.8 million. The new Grifo pumps are expected to be commissioned in the third quarter of this year and, in conjunction with the refurbished Sulzer pumps, will provide sufficient pumping capacity to keep the entire mine dewatered with a 100% pumping redundancy.

Figure 7: Two of three new high-volume Grifo pumps to be installed at the main pumping station 1,210 metres below surface.

Figure 8: One of five existing high-capacity Sulzer pumps in the main pumping station that will be refurbished.

Figure 9: Pumping station, part of the underground infrastructure upgrading.

Figure 10: Shaft 5 hoisting winder.

Figure 11:New winder control centre at Shaft 5.

About the Kipushi Mine

Originally named the Prince Léopold Mine, Kipushi was a high-grade, underground, zinc-copper mine in the Central African Copperbelt, adjacent to the town of Kipushi and approximately 30 kilometres southwest of the provincial capital of Lubumbashi. Approximately 60 million tonnes grading 11% zinc and 7% copper were mined between 1924 and 1993, producing a total of 6.6 million tonnes of zinc and 4.0 million tonnes of copper. The mine also produced 12,673 tonnes of lead and approximately 278 tonnes of germanium between 1956 and 1978.

Gécamines discovered the Big Zinc Zone before 1993 and the deposit remains unmined. Since March 2014, Ivanhoe has run an underground exploration program with the intention of confirming the historical Gecamines drilling of the Big Zinc and allowing a new current Mineral Resource to be defined. Concurrently, Ivanhoe has been looking to expand resources both along strike and at depth on both the Big Zinc Zone and the Fault Zone.

The lower levels of the mine flooded in early 2011 due to a lack of pumping maintenance over an extended period. Ivanhoe Mines (formerly Ivanplats) acquired a 68% interest in Kipushi in November 2011 and has assumed responsibility for ongoing redevelopment, dewatering and drilling. The state-owned mining company Gécamines holds the remaining 32% interest in Kipushi.

Qualified Person, Quality Control and Assurance

The Mineral Resource estimate was prepared by Mr. J. C. Witley (BSc Hons, MSc (Eng)) of the MSA Group. Mr. Witley is a member in good standing with the South African Council for Natural Scientific Professions (SACNASP) and has the appropriate relevant qualifications and experience to be considered an independent Qualified Person under the terms of National Instrument 43-101. Mr. Witley has approved the disclosure of technical information on Mineral Resources contained in this news release and has verified the technical data related thereto.

Other scientific and technical information in this news release has been reviewed and approved by Stephen Torr, P.Geo., Ivanhoe Mines’ Vice President, Project Geology and Evaluation, a Qualified Person under the terms of National Instrument 43-101. Mr. Torr is not independent of Ivanhoe Mines. Mr. Torr has verified the technical data disclosed in this news release not related to the current Mineral Resource estimate disclosed herein.

Ivanhoe Mines maintains a comprehensive chain of custody and QA-QC program on assays from its Kipushi Project. Half-sawn core was processed either at its preparation laboratory in Kamoa, DRC or its exploration preparation laboratory in Kolwezi, DRC. Prepared samples then are shipped to Bureau Veritas Minerals (BVM) Laboratories in Australia for external assay. Industry-standard certified reference materials and blanks are inserted into the sample stream prior to dispatch to BVM. Ivanhoe Mines’ QA-QC program has been set up in consultation with MSA Group (Pty.) Ltd., of Johannesburg.

Ivanhoe Mines will be filing a NI 43-101 Technical Report in respect of the current Mineral Resource estimate disclosed herein, within 45 days of this news release.

About Ivanhoe Mines

In addition to the Kipushi Project, Ivanhoe Mines is developing two other principal projects:

- The Kamoa copper discovery in a previously unknown extension of the Central African Copperbelt in the Democratic Republic of Congo’s southern Lualaba province. In March 2015, members of the Ivanhoe Mines exploration team received the prestigious Thayer Lindsley Award from the Prospectors & Developers Association of Canada for the Kamoa copper discovery, recognized as the year’s top international mineral discovery. On December 8, 2015, Ivanhoe and China’s Zijin Mining Group completed a landmark agreement to co-develop the world-scale Kamoa discovery.

- A multi-phased mine development on its 64%-owned Platreef discovery of platinum, palladium, nickel, copper, gold and rhodium in South Africa’s Bushveld Complex. The South African beneficiaries of a broad-based, black economic empowerment structure have a 26% stake in the Platreef Project and the remaining 10% is owned by a Japanese consortium of ITOCHU Corporation; Japan Oil, Gas and Metals National Corporation; ITC Platinum Development Ltd., an ITOCHU affiliate; and Japan Gas Corporation.

Information contacts

Investors

Bill Trenaman +1.604.331.9834

Media

North America: Bob Williamson +1.604.512.4856

South Africa: Jeremy Michaels +27.82.939.4812

Website www.ivanhoemines.com

FORWARD-LOOKING STATEMENTS

Statements in this news release that are forward-looking statements are subject to various risks and uncertainties concerning the specific factors disclosed here and elsewhere in the company’s periodic filings with Canadian securities regulators. When used in this document, the words such as “could,” “plan,” “estimate,” “expect,” “intend,” “may,” “potential,” “should” and similar expressions, are forward-looking statements. Information provided in this document is necessarily summarized and may not contain all available material information.

Statements in this release that constitute forward-looking statements or information include, but are not limited to statements regarding the potential for the delineation of additional mineral resources; statements regarding expected timing and costs of US$3.8 million for installing and refurbishing the pumps at the main 1,210-metre level pumping station; and statements regarding filing a Technical Report in respect of the current Mineral Resource estimate within 45 days of this news release. Forward-looking statements involve significant risks and uncertainties, should not be read as guarantees of future performance or results, and will not necessarily be accurate indicators of whether or not such results will be achieved. All such forward-looking information and statements are based on certain assumptions and analyses made by Ivanhoe Mines’ management in light of their experience and perception of historical trends, current conditions and expected future developments, as well as other factors management believe are appropriate in the circumstances. These statements, however, are subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information or statements including, but not limited to, unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations. Other important factors that could cause actual results to differ from these forward-looking statements also include those described under the heading “Risk Factors” in the company’s most recently filed MD&A as well as in the most recent Annual Information Form filed by Ivanhoe Mines. Readers are cautioned not to place undue reliance on forward-looking information or statements.

This press release also contains references to estimates of Mineral Resources. The estimation of Mineral Resources is inherently uncertain and involves subjective judgments about many relevant factors. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The accuracy of any such estimates is a function of the quantity and quality of available data, and of the assumptions made and judgments used in engineering and geological interpretation, which may prove to be unreliable and depend, to a certain extent, upon the analysis of drilling results and statistical inferences that may ultimately prove to be inaccurate. Mineral Resource estimates may have to be re-estimated based on, among other things: (i) fluctuations in zinc, copper, or other mineral prices; (ii) results of drilling; (iii) results of metallurgical testing and other studies; (iv) changes to proposed mining operations, including dilution; (v) the evaluation of mine plans subsequent to the date of any estimates; and (vi) the possible failure to receive required permits, approvals and licences.

English

English Français

Français 日本語

日本語 中文

中文