Kipushi’s unmined Big Zinc Deposit has an estimated 10.2 million tonnes

of Measured and Indicated Mineral Resources grading 34.9% zinc, 0.65% copper,

19 grams per tonne silver and 51 grams per tonne germanium

Updated mineral resource estimate expected in June;

definitive feasibility study scheduled for release later this year

KIPUSHI, DEMOCRATIC REPUBLIC OF CONGO – Robert Friedland, Executive Chairman of Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF), and Lars-Eric Johansson, Chief Executive Officer, announced today that a large-capacity rock crusher now has been successfully installed 1,150 metres below surface at the upgraded Kipushi zinc-copper-silver-germanium mine in the Democratic Republic of Congo (DRC).

The Sandvik jaw crusher has a maximum capacity of 1,085 tonnes an hour. After the 54-tonne machine was disassembled on surface, the pieces were lowered down Kipushi’s main production shaft – Shaft 5 – and installed in the crusher chamber. Reassembly of the crusher is underway and commissioning is expected to begin in June.

“The installation of the massive new rock crusher at the bottom of Shaft 5 is a noteworthy engineering accomplishment,” said Mr. Friedland. “It marks the final, major underground infrastructure upgrading project needed to resume underground mining, crushing and hoisting operations at Kipushi.”

Main frame of the new underground rock crusher secured onto the base plate at the 1,150-metre level, ready for reassembly and commissioning.

Mr. Friedland said negotiations are ongoing with government agencies – Gécamines, the state-owned miner and Ivanhoe’s partner at Kipushi, and Société Nationale des Chemins de Fer du Congo (SNCC), the DRC’s national railway company – and potential project financiers to advance agreements to launch a new era of commercial production at Kipushi.

“Since acquiring our 68% interest in the Kipushi Project in 2011, our team has worked with Gécamines to achieve our shared objective of resuming commercial production,” Mr. Friedland added. “In parallel with ongoing mine upgrading work and completion of the definitive feasibility study, we are evaluating a number of proposals we have received to fund the remaining infrastructure construction.”

Ivanhoe’s planned resumption of production at Kipushi focused on mining the high-grade Big Zinc Deposit

The Kipushi Mine is owned by Kipushi Corporation (KICO), a joint venture between Ivanhoe Mines (68%) and Gécamines (32%). Kipushi is on the Central African Copperbelt in the province of Haut-Katanga, approximately 30 kilometres southwest of the provincial capital of Lubumbashi and less than one kilometre from the international border with Zambia.

Built and then operated by Union Minière for 42 years, Kipushi began mining a reported 18% copper from a surface open pit in 1924. Then it transitioned to become a high-grade, underground copper, zinc and germanium mine. State-owned Gécamines gained control of Kipushi in 1967 and operated the mine until 1993, when it was placed on care and maintenance due to a combination of economic and political factors. The planned restoration of production at Kipushi is based on initial mining that will be focused on the Big Zinc Deposit.

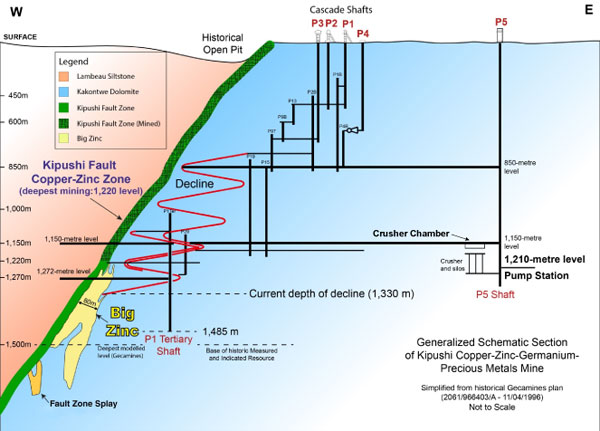

Before Kipushi was idled in 1993, Gécamines discovered the Big Zinc Deposit at a depth of approximately 1,250 metres below surface and adjacent to the producing Fault Zone (see Figure 1). No mining ever has been conducted on the Big Zinc’s mineral resources.

Ivanhoe’s drilling has upgraded and expanded the Big Zinc Deposit’s Measured and Indicated Mineral Resources to an estimated 10.2 million tonnes grading 34.9% zinc, 0.65% copper, 19 grams/tonne (g/t) silver and 51 g/t germanium, at a 7% zinc cut-off – containing an estimated 7.8 billion pounds of zinc.

During a span of 69 years, Kipushi produced a total of 6.6 million tonnes of zinc and 4.0 million tonnes of copper from 60 million tonnes of ore grading 11% zinc and approximately 7% copper. It also produced 278 tonnes of germanium and 12,673 tonnes of lead between 1956 and 1978. There is no formal record of the production of precious metals as the concentrate was shipped to Belgium and the recovery of precious metals remained undisclosed during the colonial era. However, drilling by Ivanhoe Mines has encountered significant silver values within Kipushi’s current deposits that are rich in zinc and copper.

Most of Kipushi’s historical production was from the Fault Zone, a steeply-dipping ore body rich in copper and zinc that initially was mined as an open pit. The Fault Zone extends to a depth of at least 1,800 metres below surface, along the intersection of a fault in carbonaceous dolomites (see Figure 1).

Figure 1. Schematic section of Kipushi Mine.

Key steps toward the start of a new era of mining at Kipushi

Excellent progress has been made by KICO in modernizing the Kipushi Mine’s underground infrastructure as part of preparations for the mine to resume commercial production. With the underground upgrading program nearing completion, KICO’s focus now will shift to modernizing and upgrading Kipushi’s surface infrastructure to handle and process Kipushi’s high-grade zinc and copper resources.

The current mine redevelopment plan, as outlined in the December 2017 independent, pre-feasibility study (PFS), has a construction period of less than two years, with a life-of-mine average annual production rate of 225,000 tonnes of zinc and cash costs of US$0.48/lb of zinc over an 11-year initial mine life.

The 2017 PFS estimated that Kipushi would have an after-tax NPV of US$683 million and 35% IRR, based on long-term zinc price of US$1.10/lb, with pre-production capital of US$337 million. At the current zinc price of approximately US$1.40/lb, the PFS estimated that Kipushi would have an after-tax NPV of US$1.2 billion and IRR of 51%.

A definitive feasibility study (DFS) is underway to further refine and optimize the project’s economics, taking into consideration the significant capital already invested to date on critical rehabilitation work. Ivanhoe expects to complete the DFS later this year.

“Since the PFS was issued six months ago, we have continued to make important strides toward completion of the underground infrastructure upgrading program,” Mr. Johansson said. “Our goal is to establish Kipushi as one of the world’s major zinc mines.”

Highlights of the 2017 PFS, based on a long-term zinc price of US$1.10/lb, include:

- After-tax net present value (NPV) at an 8% real discount rate of US$683 million.

- After-tax real internal rate of return (IRR) of 35.3%.

- After-tax project payback period of 2.2 years.

- Pre-production capital costs, including contingency, estimated at US$337 million.

- Existing surface and underground infrastructure allows for significantly lower capital costs than comparable greenfield development projects.

- Life-of-mine average planned zinc concentrate production of 381,000 dry tonnes per annum, with a concentrate grade of 59% zinc, is expected to rank Kipushi, once in production, among the world’s largest zinc mines.

- Life-of-mine average cash cost of US$0.48/lb of zinc is expected to rank Kipushi, once in production, in the bottom quartile of the cash cost curve for zinc producers globally.

The 2017 PFS was prepared by OreWin, MSA Group, SRK Consulting, Murray & Roberts, Golder Associates and MDM Engineering, a subsidiary of Amec Foster Wheeler. The PFS was prepared in compliance with Canadian National Instrument 43-101 – Standards of Disclosure for Mineral Projects (NI 43-101).

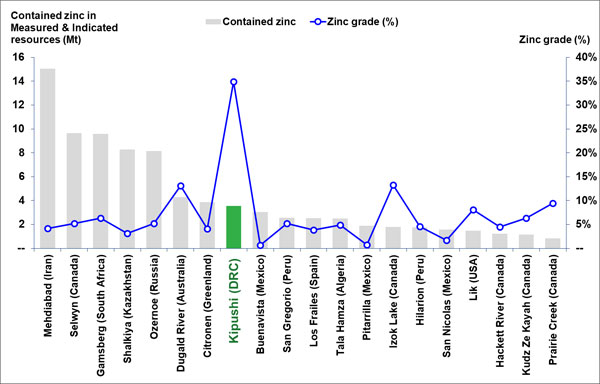

Figure 2: World’s top 20 zinc projects, by contained zinc.

Source: Wood Mackenzie.

Note: All tonnes and zinc grades of the above-mentioned projects (except for Kipushi) are based on public disclosure and have been compiled by Wood Mackenzie.

Upgrading of existing underground infrastructure nearing completion; focus now turns to upgrading surface infrastructure, including the rail siding and line from the mine to the existing network at Munama

KICO has completed the refurbishment of a significant amount of underground infrastructure at the Kipushi Project, including a series of vertical mine shafts, with associated head frames, to various depths, as well as underground mine excavations. A series of crosscuts and ventilation infrastructure still are in working condition. The underground infrastructure also includes a series of pumps to manage the influx of water into the mine. A schematic layout of the existing development is shown in Figure 1.

The main production shaft for the Kipushi Mine, Shaft 5 (labelled as P5 in Figure 1), is eight metres in diameter and 1,240 metres deep, and has been upgraded and re-commissioned. The main personnel and material winder has been upgraded and modernized to meet global industry standards and safety criteria. The Shaft 5 rock-hoisting winder, which had an annual hoisting capacity of 1.8 million tonnes, also has been upgraded to international standards and is fully operational.

The main haulage way on the 1,150-metre level between the Big Zinc access decline and Shaft 5 rock load-out facilities has been resurfaced with concrete so the mine now can use modern, trackless, mobile machinery.

In October 2017, Ivanhoe Mines and the DRC’s state-owned railway company, Société Nationale des Chemins de Fer du Congo (SNCC), signed a Memorandum of Understanding (MOU) to rebuild 34 kilometres of track to connect the Kipushi Mine with the DRC national railway at Munama, south of the mining capital of Lubumbashi.

Under the terms of the MOU, Ivanhoe has appointed R&H Rail to conduct a front-end engineering design study to assess the scope and cost of rebuilding the spur line from the Kipushi Mine to the main Lubumbashi-Sakania railway at Munama. The study is underway and construction on the Kipushi-Munama spur line could start later this year. Ivanhoe will finance the estimated US$32 million (plus contingency) capital cost for the rebuilding, which is included within the overall Kipushi 2017 PFS capital cost.

The proposed export route is to utilize the SNCC network from Kipushi to Ndola, connecting to the north-south rail corridor from Ndola to Durban. The rail corridor to Durban via Zimbabwe is fully operational and has significant excess capacity.

Optimized zinc processing methodology for the PFS

The optimized plant design used for the PFS utilizes dense media separation (DMS), followed by milling and a flotation recovery plant. The addition of milling and a flotation recovery plant resulted in an overall recovery of 89.6%, producing a consistent, high-grade concentrate of 58.9% contained zinc. DMS is a simple density-concentration technique that preliminary test work has shown yields positive results for the Kipushi material, which has a sufficient density differential between the waste rock (predominantly dolomite) and mineralization (sphalerite). Furthermore, the addition of a milling and flotation circuit to DMS is expected to improve the project economics as a result of higher concentrate grades.

Given the significant, very-high-grade zinc resource at Kipushi, which is rich in potential by-product credits including copper, silver and germanium, Ivanhoe and the Gécamines technical team are continuing to investigate additional downstream processing options.

Germanium is a strategic metal that is a key component of fibre-optic systems, infrared optics, high-efficiency solar-cell applications, and light-emitting diodes. The current spot price of germanium is approximately US$2,300 a kilogram.

New Mineral Resource estimate for Kipushi expected in June

Ivanhoe initiated a second phase of underground drilling at Kipushi in April 2017 with the goal of upgrading Inferred Mineral Resources on the Southern Zinc and Fault zones to Indicated Mineral Resources, expanding Mineral Resources in the Série Recurrent Zone and collecting additional sample material for metallurgical flotation testing.

Logging and sampling of the holes was completed at the end of 2017 and the final assays have been received. Geological interpretation of the results is ongoing and a new resource update is planned for release in June. The updated Mineral Resource will be used in the preparation of the Kipushi DFS.

The DFS will focus on the mining of Kipushi’s Big Zinc Deposit, which has an estimated 10.2 million tonnes of Measured and Indicated Mineral Resources grading 34.9% zinc. This zinc grade is more than twice as high as the Measured and Indicated Mineral Resources of the world’s next-highest-grade, major zinc project, according to Wood Mackenzie, a leading, international industry research and consulting group.

In addition to the Big Zinc Deposit, Kipushi has several copper-rich zones that also contain silver, germanium and zinc. Measured and Indicated Mineral Resources contained in the copper-rich Série Récurrente Zone, Fault Zone, and Fault Zone Splay total 1.63 million tonnes at grades of 4.01% copper, 2.87% zinc and 22 g/t silver, at a 1.5% copper cut-off, containing 144 million pounds of copper. Inferred Mineral Resources in these zones total an additional 1.64 million tonnes at grades of 3.30% copper, 6.97% zinc and 19 g/t silver.

The crusher’s largest single unit, the 19-tonne main frame, being prepared to be lowered down Shaft 5.

The crusher’s main frame at Shaft 5’s 1,150-metre-level station.

The main frame being transported to the 1,150-metre-level crusher chamber.

Main frame being moved into position at the crusher chamber.

About the Kipushi Mine

Kipushi is a historic, high-grade, copper-zinc-sliver-germanium mine that operated from 1924 to 1993 in the DRC’s Central African Copperbelt, adjacent to the town of Kipushi.

After being placed on care and maintenance in 1993, the lower levels of the mine flooded in early 2011 due to a lack of pumping maintenance over an extended period. Ivanhoe Mines acquired a 68% interest in Kipushi in November 2011 and assumed responsibility for ongoing redevelopment, dewatering and drilling. In December 2015, Ivanhoe achieved a major milestone in its upgrading of Kipushi’s underground infrastructure when the water level in Shaft 5 was pumped below the mine’s main pumping station 1,210 metres underground. The water level now is maintained below the 1,210-metre level and the mine has clear and safe access to all of the main underground workings, including the Big Zinc Deposit.

Qualified Person, Quality Control and Assurance

The scientific and technical information in this news release has been reviewed and approved by Stephen Torr, P.Geo., Ivanhoe Mines’ Vice President, Project Geology and Evaluation, a Qualified Person under the terms of National Instrument 43-101. Mr. Torr is not independent of Ivanhoe Mines. Mr. Torr has verified the technical data disclosed in this news release.

Ivanhoe has prepared and filed a current independent, NI 43-101 technical report for the Kipushi Project, titled “Kipushi 2017 Prefeasibility Study”, with an effective date of January 25, 2018, which is available under the company’s SEDAR profile at www.sedar.com and on the company’s website at www.ivanhoemines.com. The technical report includes relevant information regarding the effective dates and the assumptions, parameters and methods of the mineral resource estimates on the Kipushi Project cited in this release, as well as information regarding data verification, exploration procedures, sample preparation, analysis and security, and other matters relevant to the scientific and technical disclosure contained in this release in respect of the Kipushi Project.

About Ivanhoe Mines

Ivanhoe Mines is advancing its three principal projects in Southern Africa: 1) Mine development at the Platreef platinum-palladium-gold-nickel-copper discovery on the Northern Limb of South Africa’s Bushveld Complex; 2) mine development and exploration at the tier one Kamoa-Kakula copper discovery on the Central African Copperbelt in the DRC; and 3) upgrading at the historic, high-grade Kipushi zinc-copper-silver-germanium mine, also on the DRC’s Copperbelt. For details, visit www.ivanhoemines.com.

Information contacts

Investors

Bill Trenaman +1.604.331.9834

Media

North America: Bob Williamson +1.604.512.4856

South Africa: Jeremy Michaels +27.82.772.1122

Website www.ivanhoemines.com

Cautionary statement on forward-looking information

Certain statements in this news release constitute “forward-looking statements”or “forward-looking information”within the meaning of applicable securities laws. Such statements involve known and unknown risks, uncertainties and other factors, which may cause actual results, performance or achievements of the company, the Kipushi Project, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results, and speak only as of the date of this release.

Statements in this news release that constitute forward-looking statements or information include, but are not limited to: (1) statements regarding commissioning of the crusher is expected to begin in June; (2) statements regarding the redevelopment plan to bring Kipushi’s Big Zinc Zone into production in less than two years; (3) statements regarding successful restoration of production would establish Kipushi as the world’s highest-grade major zinc mine; (4) statements regarding the Kipushi Project having an after-tax NPV of US$683 million and an IRR of 35.3%; (5) statements regarding Kipushi has an after-tax NPV of US$1.2 billion and IRR of 51% at the current zinc price of approximately US$1.40/lb; (6) statements regarding pre-production capital estimated at US$337 million; (7) statements regarding annual production of an average of 381,000 tonnes of zinc concentrate over an 11-year initial mine life at a total cash cost of approximately US$0.48 per pound of zinc; (8) statements regarding independent research by Wood Mackenzie concludes that the Kipushi Project could rank among the world’s largest zinc mines; (9) statements regarding that Kipushi has the resources to become one of the world’s largest and lowest-cost zinc producers, plus the potential to also produce significant quantities of copper, silver and germanium; (10) statements regarding that the planned life-of-mine average annual zinc production is 225,000 tonnes and zinc head grade is 32%; (11) statements regarding that the project life-of-mine average cash cost of US$0.48/lb of zinc is expected to rank Kipushi, once in production, in the bottom quartile of the cash cost curve for zinc producers globally; (12) statements regarding the proposed rail export route for zinc concentrate to the port of Durban, South Africa; (13) statements regarding construction on the Kipushi-Munama spur rail line could start in late 2018; (14) statements regarding expected methods of mining and processing; and (15) statements that an updated Mineral Resource statement for Kipushi is expected in June 2018.

The forward-looking information and statements also includes metal price assumptions, cash flow forecasts, projected capital and operating costs, metal recoveries, mine life and production rates, and other assumptions used in the Kipushi December 2017 PFS. Readers are cautioned that actual results may vary from those presented.

All such forward-looking information and statements are based on certain assumptions and analyses made by Ivanhoe Mines’ management in light of their experience and perception of historical trends, current conditions and expected future developments, as well as other factors management believe are appropriate in the circumstances. These statements, however, are subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information or statements including, but not limited to, unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts to perform as agreed; social or labour unrest; changes in commodity prices; unexpected failure or inadequacy of infrastructure, or delays in the refurbishment or development of infrastructure, and the failure of exploration programs or other studies to deliver anticipated results or results that would justify and support continued studies, development or operations. Other important factors that could cause actual results to differ from these forward-looking statements also include those described under the heading “Risk Factors” in the company’s most recently filed MD&A as well as in the most recent Annual Information Form filed by Ivanhoe Mines. Certain of the risks that could cause the actual results to differ materially also are presented in the technical report for the Kipushi Project titled “Kipushi 2017 Prefeasibility Study” with an effective date of January 25, 2018, available on SEDAR at www.sedar.com and on the Ivanhoe Mines website at www.ivanhoemines.com.

Readers are cautioned not to place undue reliance on forward-looking information or statements.

This news release also contains references to estimates of Mineral Resources. The estimation of Mineral Resources is inherently uncertain and involves subjective judgments about many relevant factors. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The accuracy of any such estimates is a function of the quantity and quality of available data, and of the assumptions made and judgments used in engineering and geological interpretation, which may prove to be unreliable and depend, to a certain extent, upon the analysis of drilling results and statistical inferences that may ultimately prove to be inaccurate. Mineral Resource estimates may have to be re-estimated based on, among other things: (1) fluctuations in zinc, copper, or other mineral prices; (2) results of drilling; (3) results of metallurgical testing and other studies; (4) changes to proposed mining operations, including dilution; (5) the evaluation of mine plans subsequent to the date of any estimates; and (6) the possible failure to receive required permits, approvals and licences.

Although the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

English

English Français

Français 日本語

日本語 中文

中文