Construction of first mining shaft at Platreef PGM Project highlights

a year of significant progress at Ivanhoe’s three key development

projects in southern Africa

TORONTO, CANADA – Ivanhoe Mines (TSX: IVN) today announced its financial results for the year ended December 31, 2014. All figures are in US dollars unless otherwise stated.

HIGHLIGHTS

- On November 4, 2014, South Africa’s Department of Mineral Resources provided final approval of the Mining Right for the development of Ivanhoe Mines’ Platreef Project, paving the way for Ivanhoe to build a new, R13.5 billion ($1.2 billion) platinum, palladium, rhodium, gold, nickel and copper underground mine just outside Mokopane, in Limpopo province.

- In January 2015, Ivanhoe completed a pre-feasibility study for Platreef which covered the first phase of development of a large, mechanized, underground mine with an initial four-million-tonnes-per-year concentrator and associated infrastructure to support initial concentrate production by 2019. The study estimates planned initial average annual production rate of 433,000 ounces of platinum, palladium, rhodium and gold (3PE+Au), plus 19 million pounds of nickel and 12 million pounds of copper per year, at an estimated $322 per ounce of 3PE+Au, net of by-products. The feasibility study for the first phase of development is expected to commence in Q2 2015.

- Ivanhoe Mines plans to develop the Platreef underground mine in three phases — an initial annual rate of four million tonnes per year (Mtpa) to establish an operating platform to support future expansions; followed by a doubling of production to eight Mtpa; and then a third expansion phase to a steady-state 12 Mtpa. At a projected production rate of 12 Mtpa, Platreef would be among the largest platinum-group metals mines in the world.

- Construction work on a large, concrete surface collar for the 7.25-metre-diameter Shaft 1 at Platreef is advancing well and the refurbished stage and hoist winding equipment will be installed once the foundations are complete. Shaft 1, including some initial lateral, underground development work, is expected to be fully funded from dedicated funds remaining in Ivanhoe’s treasury from the $280 million received in 2011 for the sale of an 8% interest in the Platreef Project to the ITOCHU-led Japanese consortium.

- Ivanhoe has awarded the contract for design and engineering of Shaft 2, the 10-metre-diameter main production shaft that will be capable of hoisting six million tonnes a year, to South Africa-based Murray & Roberts Cementation in June 2014. This will enable Ivanhoe to start Shaft 2 development works in 2015, subject to necessary approvals and funding.

- On February 11, 2015, Ivanhoe announced that its South African subsidiary, Ivanplats, was the top-ranked platinum-sector mining company in compliance with the country’s black empowerment laws. Ivanplats achieved Level 3 status in its first verification assessment on the Broad-Based Black Economic Empowerment (BBBEE) scorecard. A total of 70% of the 700 permanent and contract workers currently employed by the company are from the local area. In March 2015, the Platreef Project achieved a significant operational safety milestone when it recorded the completion of 3.8 million person hours of work without incurring a lost-time injury.

- On March 3, 2015, members of the Ivanhoe Mines exploration team received the prestigious Thayer Lindsley Award from the Prospectors & Developers Association of Canada (PDAC) for the discovery of the Kamoa Copper Deposit in the Democratic Republic of Congo (DRC).

- The construction of the box cut for the first access declines to the initial planned underground mine at Kamoa was completed at the end of 2014. This enables commencement of construction of the twin declines designed to intersect the high-grade copper mineralization in the Kansoko Sud area, approximately 150 metres below surface. Ivanhoe’s drilling program in this area has defined a thick, near-surface zone of high-grade copper mineralization, where a recent drill hole intercepted 15.7 metres (true width) of 7.04% copper, at a 1.5% total copper cut-off. A tender for construction of the twin declines and a raise-bore ventilation shaft was issued towards the end of 2014.

- In line with the phased approach to project development outlined in the 2013 Kamoa preliminary economic assessment, the Kamoa pre-feasibility study is progressing based on the planned first phase of the project, which will be the construction of an underground operation, producing three million tonnes per year and feeding a concentrator adjacent to the mine.

- Also in the DRC, underground drilling began in March 2014 at the Kipushi copper-zinc-germanium-lead and precious-metals mine, which is southeast of Kamoa on the Central African Copperbelt in southern Katanga Province, less than one kilometre from the Zambian border. The drilling is designed to confirm and update Kipushi’s estimated historical resources and to further expand the resources on strike and at depth. More than 13,000 metres of drilling had been completed by the end of 2014.

- On February 17, 2015, Ivanhoe announced the intersection of a potential new zone of mineralization by Hole KPU072, 140 metres below the base of historical Indicated Resources of the Big Zinc. The observed intersection includes mixed massive sphalerite, chalcopyrite and minor pyrite from 417.32 metres to 420.55 metres, massive sphalerite from 420.55 metres to 468.09 metres, and massive pyrite with accessory chalcopyrite and sphalerite from 468.09 metres to 477.17 metres. The core intersection angles suggest the zone may have a true width of approximately 30 metres.

- On March 23, 2015, China-based Zijin Mining Group agreed to acquire a 9.9% stake in Ivanhoe Mines by investing approximately C$105 million to help advance Ivanhoe’s three mine-development projects in Africa. Under terms of the agreement, Ivanhoe will issue 76,817,020 common shares to Zijin through a private placement at a price of C$1.36 per share. In addition, Ivanhoe and Zijin are in detailed, friendly discussions about the strategic co-development of Ivanhoe’s Kamoa copper discovery in the Democratic Republic of Congo.

Principal Projects and Review of Activities

Ivanhoe Mines is advancing and developing its three principal projects in Southern Africa:

- The Kamoa copper discovery in a previously unknown extension of the Central African Copperbelt in the DRC’s Province of Katanga.

- The Platreef Discovery of platinum, palladium, nickel, copper, gold and rhodium on the Northern Limb of the Bushveld Complex in South Africa.

- The historic, high-grade Kipushi zinc-copper mine, also on the Copperbelt in the DRC and now being drilled and upgraded, following a care-and-maintenance program conducted between 1993 and 2011.

1. Kamoa Project

95%-owned by Ivanhoe Mines

Democratic Republic of Congo (DRC)

The Kamoa Project is a newly discovered, very large, stratiform copper deposit with adjacent prospective exploration areas within the Central African Copperbelt, approximately 25 kilometres west of the town of Kolwezi and about 270 kilometres west of the Katangan provincial capital of Lubumbashi. Ivanhoe holds its 95% interest in the Kamoa Project through a subsidiary company, Kamoa Copper SA (formerly African Minerals Barbados Limited SPRL). A 5%, non-dilutable interest in Kamoa Copper SA was transferred to the DRC government on September 11, 2012, for no consideration, pursuant to the DRC Mining Code. Ivanhoe also has offered to sell an additional 15% interest to the DRC government on commercial terms to be negotiated.

Kamoa is the world’s largest undeveloped, high-grade copper deposit. On January 17, 2013, an updated mineral resource estimate was announced that increased Kamoa’s Indicated Mineral Resources to a total of 739 million tonnes grading 2.67% copper and containing 43.5 billion pounds of copper. This was an increase of 115% over the previous estimate in September 2011 of 348 million tonnes grading 2.64% copper and containing 20.2 billion pounds of copper. Both estimates used a 1.0% copper cut-off grade and a minimum vertical mining thickness of three metres.

In addition to the Indicated Resources, the updated estimate included Inferred Mineral Resources of 227 million tonnes grading 1.96% copper and containing 9.8 billion pounds of copper, also at a 1.0% copper cut-off grade and a minimum vertical mining thickness of three metres.

At a higher, 2.0% copper cut-off grade, Kamoa’s Indicated Resources total an estimated 550 million tonnes grading 3.04% copper and containing 36.9 billion pounds of copper. At the 2.0% cut-off, Kamoa also has 93 million tonnes of Inferred Resources grading 2.64% copper, which contain an estimated 5.4 billion pounds of copper.

Diamond drilling focused on initial mining area and new exploration targets

Drilling during Q4 2014 was focused on resource infill, exploration, and geotechnical investigation. In total, 656 metres were completed in six holes, including 513 metres (four holes) drilled for infill in Kansoko Sud, 126 metres (one hole) drilled in the Kakula area for exploration and 17 metres (one hole) drilled into Kansoko Sud’s planned decline area for geotechnical purposes.

The main focus of 2014 drilling was resource infill and metallurgical studies. Six drill rigs were in operation during Q1, with a gradual reduction toward the end of the year. A total of 31,179 metres were completed during the year, comprised of 19,215 metres for resource evaluation and variability; 2,488 metres for metallurgical testing in the Kamoa Sud, Kansoko Central, Kansoko Sud and Makalu areas; 721 metres of exploration drilling in the Kansoko East area; and 7,418 metres of exploration drilling at Kakula. By the end of the second quarter, Ivanhoe entirely focused on infill drilling of Kansoko Sud to 100-metre centres and exploration drilling at Kakula. In addition, 333 metres were drilled into the decline to give a preliminary indication of the condition of the rock pre-decline tendering and cover drilling. Cover drilling is planned to take place during 2015.

A separate hydro-geological drill program was completed for future supply of mine water south of the Makalu Dome, with 1,004 metres completed in four large-diameter production boreholes. Testing has indicated that these four holes could provide a sustainable water supply for permanent operation of the mine and process plant for the initial phase of the project.

Ivanhoe plans to continue drilling in 2015 with two company-owned rigs and a recently purchased new rig that is capable of drilling to a depth of 1,000 metres. The 2015 exploration program will focus on the southern portion of the project area where the successful 2014 program highlighted a promising target — the Kakula discovery, which is similar in style and stratigraphic position to the high-grade Kansoko trend. Exploration also will continue to look for shallow, high-grade zones in the Kamoa North area.

Preparation for construction of first declines

The construction of the box cut for the first access declines to the initial, planned underground mine was completed at the end of 2014. This will enable the construction of the twin declines that have been designed to intersect the high-grade copper mineralization in the Kansoko Sud area, approximately 150 metres below the surface.

Figure 1: Completed box cut with access roadway under construction.

Ivanhoe’s drilling program in this area has defined a thick, near-surface zone of high-grade copper mineralization, where a recent drill hole intercepted 15.7 metres (true width) of 7.04% copper, at a 1.5% total copper cut-off.

A tender for construction of the twin declines to the first mining area and a raise-bore ventilation shaft was issued at the end of November. The tendered work includes the bolting, meshing and shotcreting work still required for the permanent support of the walls of the box cut. The construction of a concrete roadway, drains and de-watering sump in the box cut commenced at the end of 2014 and is due to be complete in Q3 2015.

Progress on pre-feasibility mine design, with initial development planned at Kansoko Sud

In line with the phased approach to project development outlined in the 2013 Kamoa preliminary economic assessment, the Kamoa pre-feasibility study (PFS) is progressing based on the planned first phase of the project, which will be the construction of an underground operation producing three million tonnes a year and feeding an adjacent concentrator.

The design, scheduling and cost estimation of the mining portion of the phase one PFS is nearing completion. Given the relatively un-deformed, continuous mineralization of the Kamoa resource, it is considered amenable to large-scale, mechanized stepped-room-and-pillar mining, transitioning to drift-and-fill mining in the deeper sections of the mine. Design is continuing of the paste backfill system planned to be used in the drift-and-fill mining.

Improved metallurgical test results

During 2014, bench-scale metallurgical test work for the PFS design of the concentrator was completed at the XPS laboratory in Sudbury, Canada, and the Mintek laboratory in Johannesburg, South Africa. The process flow sheet was developed based on test work on a composite sample representing the first four years of mining. The selected circuit then was subjected to additional, high-level variability tests to investigate the circuit response to feed changes later in the mine life. The results obtained confirmed composite results.

The selected processing circuit achieved a copper recovery of 88.3% and a copper concentrate grade of 39.0% on a master composite sample that was representative of the planned early years of mining. Additional test work on composite samples from early and later mining areas returned very good sulphide copper recovery results, often in excess of 90%. In addition, very low arsenic levels of 0.01% were reported. Future planned test work will include signature plots for ultrafine grinding-mill sizing, settling and filtration tests and variability test work.

Continued focus on sustainability

There remains a key focus on safety, health, environmental management and community relations at the Kamoa site. By the end of 2014, 3.9 million lost-time injury-free (LTIF) hours had been worked since the previous LTI in 2012. Ivanhoe is continuing to maintain health programs relating to malaria and HIV monitoring, prevention and treatment.

A comprehensive environmental monitoring program is in place, which includes the measurement of the levels and quality of surface and ground water and dust fallout, noise, vibration and erosion. Only one environmental concern was observed in 2014, which related to soil erosion and was immediately repaired.

A total of 495 community and stakeholder meetings were recorded in 2014 involving 6,588 participants ranging from community members and traditional leaders to governmental officials. Social and livelihood projects in 2014 included the supply of potable water to the village of Israel, the construction of a school at the village of Kaponda and support for 429 small-scale farmers.

Improved systems for monitoring and recording of environmental and community statistics were implemented. Resettlement planning and updating of the environmental and social impact assessment await the finalization of the project schedule.

2. Platreef Project

64%-owned by Ivanhoe Mines

South Africa

The Platreef Project, in South Africa’s Limpopo province, is 64%-owned by Ivanhoe through its subsidiary, Ivanplats (Pty) Ltd. (Ivanplats) and 10%-owned by a Japanese consortium of ITOCHU Corporation; ITC Platinum, an ITOCHU affiliate; Japan Oil, Gas and Metals National Corporation; and Japan Gas Corporation. The Japanese consortium’s 10% interest in the Platreef Project was acquired in two tranches for a total investment of $290 million. The remaining 26% interest is held by Ivanhoe’s broad-based, black economic empowerment (B-BBEE) partners, which include communities, employees and entrepreneurs. Ivanplats achieved Level 3 status in its first verification assessment on a B-BBEE scorecard, the highest-ranking platinum-sector mining company in compliance with South Africa’s black empowerment laws.

The Platreef Project hosts an underground deposit of thick, platinum-group metals, nickel, copper and gold mineralization in the Northern Limb of the Bushveld Complex, approximately 280 kilometres northeast of Johannesburg.

On the Northern Limb, such mineralization primarily is hosted within the Platreef, a mineralized sequence that is traced more than 30 kilometres along strike. Ivanhoe’s Platreef Project, within the southern sector of the Platreef, is comprised of three contiguous properties: Turfspruit, Macalacaskop and Rietfontein. The northernmost property, Turfspruit, is contiguous with, and along strike from, Anglo Platinum’s Mogalakwena group of properties and mining operations.

Since 2007, Ivanhoe has focused its exploration activities on defining and advancing the down-dip extension of its original Platreef discovery, now known as the Flatreef Deposit, which is viewed as being amenable to highly mechanized, underground mining methods. The Flatreef area lies entirely on the Turfspruit and Macalacaskop properties.

Figure 2: Aerial view of Platreef Project, March 11, 2015.

Mining right active

The Ivanplats mining right was officially executed by the national government’s Department of Mineral Resources on November 4, 2014. The mining right authorizes the company to exclusively mine and process platinum-group metals, nickel, copper, gold, silver, cobalt, iron, vanadium and chrome from the mining area for an initial period of 30 years, and may be renewed for an unlimited number of consecutive periods each of up to 30 years, in accordance with section 24 of the Mineral and Petroleum Resources Development Act.

Mining operations must be conducted in accordance with the Mining Work Program (MWP) and any amendment to such MWP, and with an approved Environmental Management Plan (EMP). The company commenced the roll-out of its Social and Labour Plan (SLP), which includes the planning, implementation and execution of local economic development projects, human resource development and enterprise/supplier development.

Shaft 1 construction

The formal activation of the mining right followed a six-month suspension of construction activity at the site of Ivanhoe’s planned Platreef underground mine. Equipment was returned to the site on December 1, 2014, and normal operations have been successfully re-established.

Figure 3: Shaft 1 box cut first blast.

The main focus at site is the completion of the excavation at the box cut to establish access for the construction of the large concrete surface collar for Shaft 1. Other work on site includes the terrace for the 5MVA temporary power supply, pollution-control dam, offices and training facilities. The project completed the first successful blasts in the Shaft 1 box cut and the pollution control dam in February 2015.

A total of 70% of the 700 permanent and contract workers currently employed by the company are from the local area.

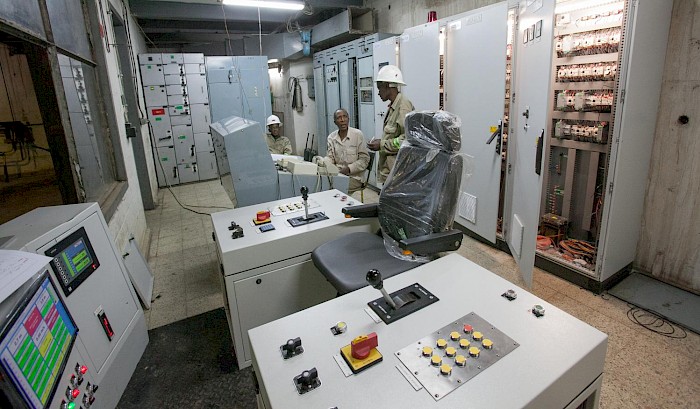

Figures 4 and 5: Some of the members of the Platreef Project’s construction and refurbishment teams.

Planned phased approach to a large, underground, mechanized mine at Platreef

The company completed a pre-feasibility study (PFS) in January 2015 that covered the first phase of development that is expected to include construction of an underground mine, concentrator and other associated infrastructure to support initial concentrate production by 2019. As the first phase is being developed and commissioned, there will be opportunities to refine the timing and scope of subsequent phases of production.

PFS highlights

- Development of a large, mechanized, underground mine with an initial four-million-tonne per year concentrator and associated infrastructure.

- Planned initial average annual production rate of 433,000 ounces of platinum, palladium, rhodium and gold (3PE+Au), plus 19 million pounds of nickel and 12 million pounds of copper.

- Estimated pre-production capital requirement of approximately $1.2 billion, including $114 million in contingencies, at a ZAR:USD exchange rate of 11 to 1.

- Platreef would rank at the bottom of the cash-cost curve, at an estimated $322 per ounce of 3PE+Au, net of by-products.

- The planned Platreef mine is projected to require a workforce of approximately 2,200 within four years of the start of production.

- After-tax Net Present Value (NPV) of $972 million, at an 8% discount rate.

- After-tax Internal Rate of Return (IRR) of 13%.

The scenarios describe a staged approach, where there would be opportunities to expand the operation depending on demand, smelting and refining capacity and capital availability. As the Phase 1 production scenario is developed and placed into production, there is expected to be an opportunity to modify and optimize the subsequent phases, allowing for changes to the timing of capacity expansions to suit market conditions.

The company also has retained Whittle Consulting of Melbourne, Australia, to conduct an optimization study based on the Platreef PFS. This work has progressed well and certain recommendations from the study will be carried forward into the feasibility study during 2015.

Mineral resources in the Flatreef underground discovery

The Flatreef Mineral Resource, with a strike length of 6.5 kilometres, lies predominantly within a flat to gently dipping portion of the Platreef mineralized belt at relatively shallow depths of approximately 700 to 1,100 metres below surface.

The Flatreef Deposit is characterized by its very large vertical thicknesses of high-grade mineralization and a platinum-to-palladium ratio of approximately 1:1, which is significantly higher than other recent PGM discoveries on the Bushveld’s Northern Limb. The grade shells used to constrain mineralization in the Flatreef Indicated Mineral Resource area have average true thicknesses of approximately 24 metres at a cut-off grade of 2.0 grams per tonne (g/t) of platinum, palladium and gold (2PE+Au). The Indicated Mineral Resource grade at equivalent 2.0 gram-per-tonne 3PE+Au cut-off is 4.1 g/t 3PE+Au, 0.34% nickel and 0.17% copper. Flatreef’s Indicated Mineral Resources of 214 million tonnes contain an estimated 28.5 million ounces of platinum, palladium, gold and rhodium, 1.6 billion pounds of nickel and 0.8 billion pounds of copper. The company has declared an initial Probable Mineral Reserve of 15.5 million ounces of platinum, palladium, rhodium and gold, using a declining Net Smelter Return (NSR) cut-off of $100/t-$80/t.

Mining methods

Mining zones in the current Platreef mine plan occur at depths ranging from approximately 700 metres to 1,200 metres below the surface. Four vertical shafts will provide access to the mine. Shaft 2 will host the main personnel, material and ore handling system, while Shafts 1, 3 and 4 will provide ventilation to and from the underground working. Shaft 1, now under development, will be used for initial access to the ore body and early underground development.

Mining will be performed using highly productive, mechanized methods, including long-hole stoping and drift-and-fill mining. The ore will be hauled from the stopes to the bottom of Shaft 2, where it will be crushed and hoisted to surface.

Metallurgical and processing

Metallurgical test work has focused on maximizing the recovery of platinum-group elements (PGE) and base metals, while producing an acceptably high-grade concentrate suitable for further processing and/or sale to a third party. The three main geo-metallurgical units and composites have produced smelter-grade final concentrates of approximately 85 g/t PGE + gold at acceptable PGE recoveries. Testwork also has shown that the material is amenable to treatment by conventional flotation without the need for re-grinding. Batch open-circuit and locked-cycle flotation testwork has been performed.

Comminution and flotation testwork has indicated that the optimum grind size is 80% passing 75 µm (micrometres), which is consistent with sizes commonly reported by platinum mines in South Africa.

Improved flotation performance has been achieved using stainless-steel grinding media or high-chrome grinding media as opposed to carbon-steel media. The inclusion of post-mill conditioning of solids prior to flotation, as well as a split-cleaner flotation circuit configuration in which the fast-floating fraction is treated in a separate cleaner circuit to the medium- and slow-floating fractions, resulted in improved PGE, copper and nickel recoveries.

Platreef ore is classified as being hard to very hard, and thus not suitable for semi-autogenous grinding. A multi-stage crushing and ball-milling circuit is the preferred option.

A two-phased development approach was used for PFS flow-sheet design. The selected flow sheet is comprised of a four-million-tonne per year, three-stage crushing circuit, feeding crushed material to two parallel milling-flotation modules, each with a capacity of two million tonnes per year. Flotation is followed by a four-million-tonne per year tailings handling and concentrate thickening, filtration and storage circuit.

Shafts 1 and 2

Surface construction work for Shaft 1, which was suspended on May 26, 2014, continued following the execution of the mining right. Shaft 1 will have an internal diameter of 7.25 metres, with an annual planned hoisting capacity of 2.5 million tonnes. It is projected to reach a total depth of 975 metres in 2018. South Africa-based Aveng Mining, the shaft-sinking contractor, is responsible for the excavation of the box-cut access for the shaft collar and vent plenum and will be the sinking contractor for Shaft 1. The sinking stage and winding equipment have been refurbished and are being stored off-site. The fabrication of the temporary, sinking head frame and centre tower has begun.

Figure 6: Refurbished winding equipment for Shaft 1.

Shaft 1, including some initial lateral, underground development work, is expected to be fully funded from dedicated funds remaining in Ivanhoe’s treasury from the $280 million received in 2011 for the sale of an 8% interest in the Platreef Project to the ITOCHU-led Japanese consortium.

Ivanhoe awarded the contract for design and engineering of Shaft 2, the 10-metre-diameter main production shaft that will be capable of hoisting six million tonnes a year, to South Africa-based Murray & Roberts Cementation in June 2014. This will enable Ivanhoe to start Shaft 2 development works in 2015, subject to necessary approvals and funding. The box-cut designs are complete and the contract for the early engineering works for the winding equipment has been awarded to South Africa-based FLSmidth.

Bulk water and electricity supply

The Olifants River Water Resource Development Project (ORWRDP) is designed to deliver water to the Eastern and Northern limbs of South Africa’s Bushveld Igneous Complex. The project consists of the new De Hoop Dam, the raised wall of the Flag Boshielo Dam, and related pipeline infrastructure that ultimately will deliver water to Pruissen, southeast of the Northern Limb. The Pruissen Pipeline Project will be developed to deliver water onward from Pruissen to the municipalities, communities and mining projects on the Northern Limb. Ivanhoe is a member of the ORWRDP’s Joint Water Forum.

Participants in the water development scheme are required to indicate their water requirements so that the total water demand may be calculated relative to the scheme’s capacity. The Platreef Project’s water requirement for the first phase of development is projected to peak at approximately 10 million litres per day. Ivanhoe also is investigating various alternative water sources.

The Platreef Project’s power requirement for a four-million-tonne per year underground mine, concentrator and associated infrastructure has been estimated at approximately 100MVA. As power is required for the initial mine development (shaft sinking), prior to the main power supply being available, an agreement with Eskom has been reached for the supply of 5MVA of temporary construction power.

Exploration and resource expansion drilling

Zone 1 resource-expansion drilling, which was suspended on May 26, 2014, resumed on December 1, 2014, following the activation of the mining right. Total drilling for the fourth quarter was 6,838 metres in seven holes. The initial 2014 drill program was revised and rescheduled as a result of the suspension of drilling activities between May and December. A total of 46 holes (46,550 metres) were drilled during 2014. The remainder of the metallurgical bulk sample and comminution drilling also was completed, totalling 4,464 meters in seven drill holes. The remaining 10 holes of the planned 2014 drilling program were completed on February 11, 2015.

Platreef geologists continue to focus on integrating the 3D seismic data acquired in 2014 with other geophysical data sources. A comprehensive logging and interpretative program was a major focus in 2014. This work is nearing completion and will form the basis of a new resource estimate for the upcoming feasibility study.

Job-skills training and environmental management commitments

As required under South African legislation, and in conjunction with the approval of the mining right, an integrated water-use licence application was submitted to the Department of Water and Sanitation (DWS); a waste-management licence application was submitted to the National Department of Environmental Affairs; and an application for environmental authorization was submitted to the Limpopo Department of Economic Development, Environment and Tourism (LEDET). Extensive environmental, social and engineering baseline studies were conducted in 2013 in support of these applications.

The Platreef Project received environmental authorization in June 2014 from LEDET. Ivanhoe is working closely with this department to ensure continual compliance during the implementation of the approved environmental management plan and the conditions stipulated in the environmental authorization. Authorization also was received from the DWS for the extraction of specified quantities of water from groundwater resources.

Ivanhoe has engaged with the South African Heritage Resources Agency (SAHRA) to obtain input and guidance on the management of archaeological and heritage resources in the area.

The Platreef Project recently achieved more than 3,800,000 LTIF man-hours. Ivanhoe is committed to developing, implementing and maintaining the highest standards of occupational health, safety, environment and welfare management. Through teamwork, and in partnership with employees, consultants and contractors, Ivanhoe will endeavour to develop and sustain a culture of preventing harm to employees, contractors, communities and other stakeholders, and the environment, through the implementation of an effective health, safety and environmental management system and best practices.

Following the activation of the mining right in November 2014, Ivanhoe began investing in its Social and Labour Plan, to which the company has pledged a total of R160 million ($14 million) during the next five years. The approved plan includes R67.2 million ($6 million) for the development of job skills among local residents and R87.7 million ($8 million) for local economic development projects. This allocation includes R26 million ($2 million) to build a community skills development and training facility in the Mokopane area as part of Ivanhoe’s objective of helping to establish a roster of qualified, local candidates for jobs at the mine and its associated minerals processing plant. The facility will be accredited by the Mining Qualifications Authority (MQA).

In addition to its SLP and B-BBEE commitments, Ivanhoe has begun an R11 million ($1 million) water harvesting and sanitation project in its host communities. The Platreef Project will provide internships to help university students complete practical components of their studies and, in the process, provide the mine with potential candidates for permanent employment.

Ivanhoe has initiated a R24 million ($2 million) partnership between South Africa’s University of Limpopo and Laurentian University in Canada to develop and equip Limpopo’s geology department to improve its curriculum choices for students, conduct research on the Platreef Project and offer post-graduate studies in geology. Ivanhoe will allocate approximately R12 million ($1 million) to the University of Limpopo and R12 million ($1 million) to Laurentian University over the next five years, and has committed to renewing the partnership for a further five-year period.

3. Kipushi Project

68%-owned by Ivanhoe Mines

Democratic Republic of Congo (DRC)

The Kipushi copper-zinc-germanium-lead mine, in the Democratic Republic of Congo’s southern Katanga province, is adjacent to the town of Kipushi and approximately 30 kilometres southwest of the provincial capital of Lubumbashi. It also is located on the Central African Copperbelt, southeast of Ivanhoe’s Kamoa Project, and less than one kilometre from the Zambian border. Ivanhoe acquired its 68% interest in the Kipushi Project in November 2011; the balance of 32% is held by the state-owned mining company, La Générale des Carrières et des Mines (Gécamines).

Project development and infrastructure

Work began in early March 2014 on the planned underground diamond-drilling program at the Kipushi Project, a major advance made possible by the ongoing dewatering program directed by Ivanhoe during the past three years following its acquisition of the historic mine in November 2011.

The mine, which had been placed on care and maintenance in 1993, flooded in early 2011 due to a lack of pump maintenance over an extended period. Water reached 851 metres below surface at its peak. A major milestone was reached in December 2013 when Ivanhoe restored access to the mine’s principal haulage level at 1,150 metres below the surface.

Since then, crews have been upgrading underground infrastructure to support the drilling program. Recent improvements have included the establishment of pump stations at the 1,112-metre and 1,272-metre levels, ventilation along the hanging-wall drift on the 1,272-metre level, continued removal of corroded ventilation column from Shaft 5 and inspections of all shaft conveyances, ropes and guides.

Water levels are stabilized below the 1,150-metre-level haulway and 1,272-metre-level hanging-wall drift, enabling access for drilling, with two rigs targeting the Série Récurrente and Big Zinc mineralization.

Figure 7: New winder control centre at Shaft 5.

Figure 8: Refurbished shaft equipment.

Figure 9: Underground tunnel upgrading work.

Confirmatory and exploration drilling

Ivanhoe’s underground drilling program at Kipushi is designed to confirm and update the mine’s estimated historical resources and to further expand the resources along strike and at depth. More than 13,000 metres of drilling had been completed by the end of 2014.

A total of 4,078 metres in 19 drill holes were completed in Q4 2014 in the Big Zinc, Série Récurrente and Nord Riche zones. A total of 13,227 metres were drilled in 70 holes in 2014.

Figure 10: Underground exploration drilling.

Figure 11: A total of 13,227 metres were drilled in 70 holes in 2014.

Ivanhoe released additional drill results from the Kipushi Project on November 24, 2014 including:

| Hole | Target zone | Intercept width (m)* |

Zinc (%) |

Copper (%) |

Silver (g/t) |

Germanium (g/t) |

Gold (g/t) |

|---|---|---|---|---|---|---|---|

| KPU040 | Big Zinc | 70 | 43.0 | 5.5 | 244 | 71 | |

| including | 34.5 | 35.1 | 10.7 | 479 | 77 | 0.30 | |

| including | 9.7 | 19.9 | 21.1 | 1,573 | 65 | 0.80 | |

| KPU042 | Big Zinc | 43.2 | 42.0 | 0.5 | 14 | 45 | |

| KPU042 | Big Zinc | 12.9 | 46.9 | 0.3 | 5.0 | 86 | |

| KPU033 | Big Zinc | 37.9 | 42.0 | 0.3 | 10 | 36 | |

| KPU037 | Big Zinc | 27.5 | 40.6 | 0.4 | 19 | 43 | |

| KPU026 | Série Récurrente | 4.4 | 17.3 | 15.6 | 38.0 | ||

| KPU045 | Série Récurrente | 5.0 | 41.3 | 3.3 | 24.0 | ||

| KPU028 | Nord Riche | 7.1 | 0.1 | 3.6 | 6.0 | ||

| KPU032 | Nord Riche | 24.2 | 23.8 | 2.8 | 8.0 | ||

| including | 6.0 | 24.2 | 10.9 | 31 | |||

Ivanhoe Mines also reported the following additional assay results on February 17, 2015:

| Hole | Target zone | Intercept width (m)* |

Zinc (%) |

Copper (%) |

Silver (g/t) |

Germanium (g/t) |

Gold (g/t) |

|---|---|---|---|---|---|---|---|

| KPU051 | Big Zinc | 188.5 | 49.7 | 0.3 | 15 | 58 | |

| KPU055 | Big Zinc | 162.9 | 51.1 | 0.4 | 11 | 59 | |

| KPU057 | Big Zinc | 175.7 | 50.3 | 0.3 | 11 | 27 | |

| KPU058 | Big Zinc | 41.4 | 42.1 | 3.8 | 54 | 71 | |

| including | 6.0 | 6.0 | 22.6 | 203 | 177 | ||

| KPU061 | Big Zinc | 75.6 | 46.2 | 0.3 | 20 | 89 | |

| KPU061 | Big Zinc | 64.9 | 44.7 | 1.1 | 14 | 128 | |

| KPU049 | Série Récurrente | 9.7 true | 11.8 | 6.0 | 73.0 | ||

| including | 6.4 true | 7.7 | 16.8 | 104 | |||

* Intercept widths are measured along core axis and do not represent true widths except where indicated

The February 17, 2015, news release also included the intersection of a potential new zone of mineralization in Hole KPU072, 140 metres below the base of Big Zinc’s historical Indicated Resources, including mixed massive sphalerite, chalcopyrite and minor pyrite from 417.32 metres to 420.55 metres; massive sphalerite from 420.55 metres to 468.09 metres; and massive pyrite with accessory chalcopyrite and sphalerite from 468.09 metres to 477.17 metres. The core intersection angles suggest the zone may have a true width of approximately 30 metres.

Full details of the drill results reported in November 24, 2014 and February 17, 2015 are included in news releases posted on Ivanhoe Mines website at www.ivanhoemines.com.

Drilling in the Big Zinc was designed to test previous resource drilling by Gécamines through the drilling of twin holes, replacement holes (where sampling was insufficient) and infill holes. In addition, further holes have been used to test the extent of the mineralized zone. Generally, the boundaries of the Big Zinc remain unchanged and the Gécamines model has been confirmed. However, additional drilling has expanded the southern limit of the Big Zinc beyond the Gécamines model.

Drilling in the Upper Kakontwe/Série Récurrente zone during 2014 located a copper-rich massive sulphide body at the level of drilling (from 1,200 metres to 1,300 metres below surface). This mineralized zone is below the level of historical Gécamines drilling, and historical Measured and Indicated Resources on the Série Récurrente zone.

Kipushi’s 68 years of production history

Following its start-up in 1924 as the Prince Léopold Mine, available records show that Kipushi produced a total of 6.6 million tonnes of zinc and 4.0 million tonnes of copper — from 60 million tonnes grading 11% zinc and approximately 7% copper — until political instability prompted the suspension of operations in 1993. The mine also produced 278 tonnes of germanium between 1956 and 1978.

In addition to the recorded production of copper, zinc, lead and germanium, Gécamines’ mine-level plans for Kipushi also report the presence of precious metals, specifically silver and rhenium. There is no formal record of the production of precious metals on the property.

SELECTED ANNUAL FINANCIAL INFORMATION

This selected financial information is in accordance with IFRS as presented in the annual consolidated financial statements. Ivanhoe had no operating revenue in any financial reporting period and did not declare or pay any dividend or distribution in any financial reporting period.

Review of the year ended December 31, 2014 vs. December 31, 2013

The company’s total comprehensive loss for the year ending December 31, 2014 of $260.2 million, was $224.1 million lower than for the same period in 2013 ($484.3 million). The decrease was attributable mainly to the impairment of the Kipushi mineral property, goodwill and related loans and advances that had a post-tax effect of $258.6 million recognized in 2013. This was partially offset by the shared-based payment expense of $88.6 million as a result of the Platreef B-BBEE transaction in 2014. The remainder of the decrease resulted from the $37.7 million year on year decrease in the exploration and project expenditure.

Financial position as at December 31, 2014 vs. December 31, 2013

The company’s total assets decreased by $34.5 million, from $287.6 million as at December 31, 2013 to $253.1 million as at December 31, 2014. This mainly was due to a $57.8 million decrease in short-term deposits and cash and cash equivalents that was partially offset by the increase in property, plant and equipment of $15.4 million.

The company utilized $179.9 million of its cash resources in its operations and earned interest income of $1.0 million on cash balances in the year ended December 31, 2014. A total of $26.2 million was spent to acquire property, plant and equipment. This mainly was for the initial development of the Platreef Project’s Shaft 1 and the Kamoa Project’s box cut.

The company generated cash inflow from financing activities during the year ending December 31, 2014, of $153 million. This mainly was a result of the public offering and a concurrent private placement that Ivanhoe completed in June and July for a total issuance of 115,000,767 units. Each unit consisted of one Class A common share and one Class A common share purchase warrant, which were sold at a price of C$1.50 per unit and raised total gross proceeds of C$173 million (net proceeds of $151 million).

The company’s total liabilities decreased to $50.7 million as at December 31, 2014, from $60.3 million as at December 31, 2013. This mainly was due to the settlement of the unpaid legal settlement expense on the receipt of the Platreef Project’s mining right, as well as a decrease in indirect taxes payable of $10.3 million. The financial liability arose with the issuance of the purchase warrants in Q2 2014 and had a fair value of $6.9 million at December 31, 2014.

The company intends to dispose of its Australian subsidiaries and therefore has classified the related assets and liabilities as held for sale. On November 23, 2014 the company agreed to dispose of the entirety of its Australian assets to a subsidiary of Clean Teq Holdings Limited (Clean Teq). The company will receive approximately A$1 million worth of shares of Clean Teq, an A$3 million promissory note and a 2.5% NSR royalty over these assets. The transaction is expected to be completed by the end of the first quarter of 2015. As at December 31, 2014, the carrying value of assets held for sale amounted to $3.0 million.

LIQUIDITY AND CAPITAL RESOURCES

The company closed a non-brokered private placement for C$108 million ($105 million) in Q4 2013 and completed a public offering and concurrent private placement for gross proceeds of C$169 million ($154 million) in Q2 2014. In addition, Robert Friedland also fully exercised his option to purchase an additional 2.5 million units, for net proceeds to the company of C$3.75 million in July 2014.

The company had $111.0 million in cash and cash equivalents and $55.2 million in short-term deposits as at December 31, 2014. Certain of the company’s cash and cash equivalents and short-term deposits, having an aggregate value of $108.8 million, are subject to contractual restrictions as to their use and are reserved for the Platreef Project.

As at December 31, 2014, the company had consolidated working capital of approximately $162.1 million, compared to $201.7 million at December 31, 2013. The Platreef Project working capital is restricted and amounted to $104.3 million at December 31, 2014, and $161.6 million at December 31, 2013. Excluding the Platreef Project working capital, the resultant working capital was $57.8 million at December 31, 2014, and $40.1 million at December 31, 2013. The company believes it has sufficient resources to cover its short-term cash requirements. However, the company’s access to financing is always uncertain and there can be no assurance that additional funding will be available to the company in the near future.

On March 23, 2015, the company announced that China-based Zijin Mining Group has agreed to acquire a 9.9% interest in Ivanhoe Mines by investing approximately C$105 million to help advance Ivanhoe’s three mine-development projects in Africa. Under terms of the agreement, Ivanhoe will issue 76,817,020 common shares to Zijin through a private placement at a price of C$1.36 per share. The private placement is scheduled to close on or about April 20, 2015, subject to receipt of the approval of the Toronto Stock Exchange, and receipt by Zijin of approvals from the Chinese government or its relevant authorized departments.

The company’s main objectives for 2015 at the Kamoa Project are the finalization of the phase 1 PFS, commencement of the phase 1 feasibility study, subject to funding, starting construction of the twin decline at Kamoa and the continuation of drilling; to finalize the optimization study, commence the feasibility study and complete the Shaft 2 design at the Platreef Project; and to complete the underground drilling program and a development plan for the Kipushi Project.

This release should be read in conjunction with Ivanhoe Mines’ audited 2014 Financial Statements and Management’s Discussion and Analysis report available at www.ivanhoemines.com and at www.sedar.com.

Qualified Person

Disclosures of a scientific or technical nature in this release have been reviewed and approved by Stephen Torr, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Ivanhoe has prepared a NI 43-101 compliant technical report for each of the Kamoa Project, the Platreef Project and the Kipushi Project, which are available under the company’s SEDAR profile at www.sedar.com. These technical reports include relevant information regarding the effective date and the assumptions, parameters and methods of the mineral resource estimates on the Kamoa Project and Platreef Project cited in this release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this release in respect of the Kamoa Project, Platreef Project and Kipushi Project.

Information contacts

Investors

Bill Trenaman +1.604.331.9834

Media

North America: Bob Williamson +1.604.512.4856

South Africa: Jeremy Michaels +27.11.088.4300

Website www.ivanhoemines.com

Cautionary statement on forward-looking information

Certain statements in this release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws, including, without limitation, the timing and results of: (i) a pre-feasibility study (PFS) at the Kamoa Project; (ii) statements regarding the expected date that the development of the first set of Kamoa twin declines is to begin; (iii) statements regarding the declines having been designed to intersect the high-grade copper mineralization in the Kansoko Sud area; (iv) statements regarding the projected depth of Shaft 1 at the Platreef Project in 2018 and the timing of the commencement of the start of Shaft 2 development; (v) statements regarding underground mining to use mechanized room-and-pillar and drift-and-fill methods; (vi) efforts to upgrade historical resource estimates at the Kipushi Project; (vii) the de-watering program at the Kipushi Project; and (viii) statements regarding the timing, size and objectives for completion of drilling programs. As well, the results of the preliminary economic assessment of the Kamoa Project and the prefeasibility study of the Platreef Project constitute forward-looking information, and include future estimates of internal rates of return, net present value, future production, estimates of cash cost, proposed mining plans and methods, mine life estimates, cash flow forecasts, metal recoveries, and estimates of capital and operating costs. Such statements involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results and speak only as of the date of this release.

This release also contains references to estimates of Mineral Resources. The estimation of Mineral Resources is inherently uncertain and involves subjective judgments about many relevant factors. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The accuracy of any such estimates is a function of the quantity and quality of available data, and of the assumptions made and judgments used in engineering and geological interpretation (including estimated future production from the company’s projects, the anticipated tonnages and grades that will be mined and the estimated level of recovery that will be realized), which may prove to be unreliable and depend, to a certain extent, upon the analysis of drilling results and statistical inferences that ultimately may prove to be inaccurate. Mineral Resource estimates may have to be re-estimated based on: (i) fluctuations in copper, nickel, platinum-group elements (PGE), gold or other mineral prices; (ii) results of drilling, (iii) metallurgical testing and other studies; (iv) proposed mining operations, including dilution; (v) the evaluation of mine plans subsequent to the date of any estimates; and (vi) the possible failure to receive required permits, approvals and licences.

Forward-looking statements involve significant risks and uncertainties, should not be read as guarantees of future performance or results, and will not necessarily be accurate indicators of whether or not such results will be achieved. A number of factors could cause actual results to differ materially from the results discussed in the forward-looking statements, including, but not limited to, the factors discussed below and under “Risk Factors”, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

Although the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

The company’s actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors set forth in the “Risk Factors” section in the company’s MD&A.

English

English Français

Français 日本語

日本語 中文

中文