Monthly development in June well ahead of plan with 1,729 metres achieved

Kakula’s 2,000-tonne-per-hour ore conveyor system begins operation

All major equipment and the majority of structural steel now on site, or en route, for Kakula’s first phase 3.8-million-tonne-per-annum processing plant scheduled to begin operations in Q3 2021

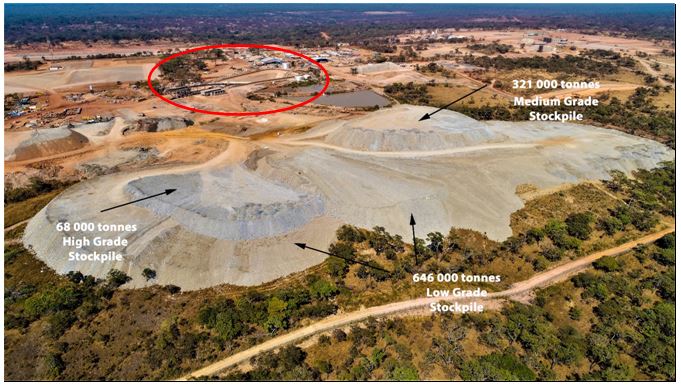

Surface stockpiles now contain an estimated 68,000 tonnes of ore grading 5.90% copper and 394,000 tonnes of medium-grade ore grading 2.71% copper, including satellite stockpiles at Kakula South and Kansoko

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX:IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun announced today that underground development at the Kakula Copper Mine continues to exceed expectations with more than 17 kilometres now complete, which is 5.1 kilometres ahead of schedule. In June, the mining team achieved 1,729 metres of underground development – 575 metres ahead of plan for the month.

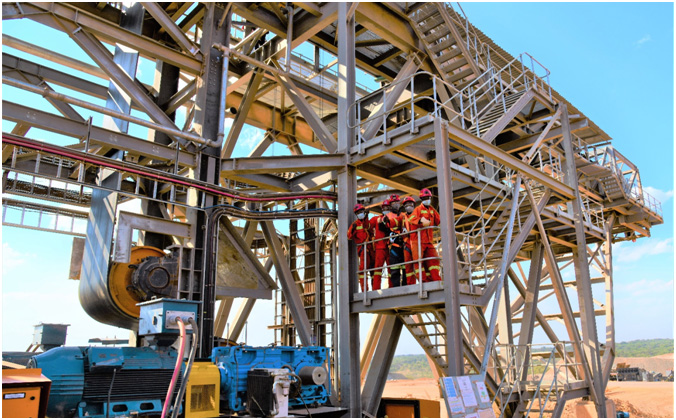

Kakula’s 2,000-tonne-per-hour ore conveyor system began operations in June, which will further increase the mine’s pace of underground development.

The majority of the development headings at the Kakula Mine currently are traversing medium-grade sections of the orebody, with average grades ranging between 3% and 5% copper. Several development headings are continuing in high-grade zones grading more than 8% copper, and this ore is being placed on a dedicated, high-grade surface stockpile at Kakula North that now totals approximately 68,000 tonnes grading an estimated 5.90% copper. The medium-grade surface stockpiles at Kakula North, Kakula South and Kansoko together contain an additional 394,000 tonnes grading an estimated 2.71% copper.

As Kakula’s underground development progresses over the next few months, the majority of the headings are expected to transition into the high-grade ore zones.

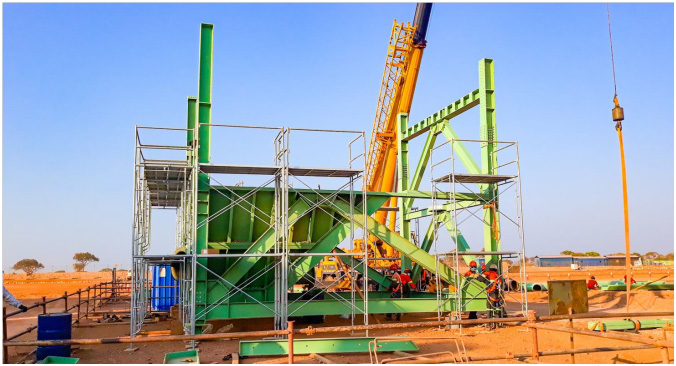

More than 200 truck loads, consisting mainly of structural steel and equipment for Kakula’s initial 3.8-million-tonne-per-annum processing plant, were received on site in June and construction of the plant is progressing rapidly. Fabrication of the plant’s largest components – two ball mills each measuring 9.75 metres (32 feet) long and 6.1 metres (20 feet) in diameter – has been completed at CITIC Heavy Industries’ factory in Luoyang, China, and shipping of the components is underway.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the DRC government (20%).

Aerial view of the Kakula Mine showing the tonnes and grade of the main pre-production stockpiles. The northern declines and ore conveyor system are circled in red and the processing plant is in the upper right corner.

Kakula southern decline and ore stockpile containing approximately 38,000 tonnes of medium-grade ore.

Kansoko decline and ore stockpile containing approximately 35,000 tonnes of medium-grade ore.

Kakula’s high-capacity ore conveyor system begins operation

Kakula’s decline conveyor system that will transport ore from underground to surface now is operational. Final commissioning of the full system (including the fire suppression system and all safety components) is underway and is scheduled to be completed around mid-July. The conveyor system has the capacity to transport 2,000 tonnes of ore per hour from underground to surface.

The conveyor system substantially shortens the haulage distance for the mine’s truck fleet; significantly increasing productivity, and lowering mining and maintenance costs.

Construction of the surface conveyor system has commenced and the first steel has been delivered to site. The surface conveyor system will transport ore from the decline conveyor system to the main processing plant stockpile. Forecast completion date is scheduled for Q1 2021.

Kakula’s first ore being transported to surface on the new conveyor system.

Click here to watch a short video of the first ore being delivered to surface via the new rock-handling conveyor system: https://player.vimeo.com/video/431759826

Click here to watch a short video of the first ore being dumped into an underground ore bin for conveyance to surface: https://player.vimeo.com/video/433659430

A 63-tonne Sandvik truck dumps the first load of ore into Kakula’s east tip bin, for transportation to surface via the new conveyor system.

Mioi Kabinda (left) and Kifumbe Bijimba (right) with the newly-installed magnet and rock breaker at the east ore tip bin, part of the underground ore handling system at the Kakula Mine.

Team members from DRC-based Kamoa Kakula Construction Company (KKCC), mark the completion of erecting the high-capacity decline conveyor system that now is transporting copper ore from Kakula’s underground workings to surface.

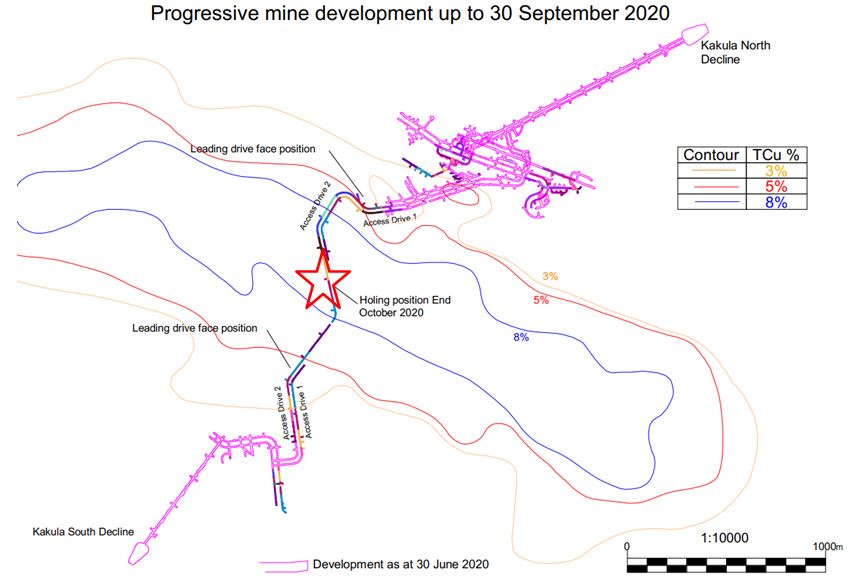

Development of the Kakula Mine, the first deposit to be placed into production on the 400-square-kilometre Kamoa-Kakula mining licence, is well ahead of schedule. Mine access drives 1 and 2 (interconnected, parallel tunnels that will provide access to ore zones) continue to progress well towards the southern portion of the orebody.

Development also is well advanced on the eastern perimeter drives and the room-and-pillar mining area. Development from the southern portal has reached south access drives 1 and 2, with mining crews working to establish the connection of these drives with mine access drives 1 and 2 from the north side of the orebody. The northern and southern access drives are scheduled to be joined by the end of October 2020.

Underground mining also is occurring at the Kansoko Mine, located at the Kamoa deposit approximately 10 kilometres north of the Kakula Mine. Kansoko is development ready and currently is being used to train young Congolese mining crews.

The main surface exhaust ventilation fans (VS#2) are progressing well with fan fabrication on schedule and the ventilation shaft raise boring complete. The NE#1 fan station pilot hole has commenced with fabrication of the fans scheduled to start this month. The third underground water pumping train at Kakula’s main decline pumping chamber has been commissioned, increasing the mine’s pumping capacity to 600 litres per second.

In parallel with the construction of Kamoa-Kakula’s phase 1 Kakula Mine, work is progressing on the independent Kakula definitive feasibility study (DFS) and an updated Integrated Development Plan for the entire Kamoa-Kakula mining complex, which is expected to be finalized this month. The Integrated Development Plan will include details on the planned expansion phases for the greater Kamoa-Kakula mining complex, incorporating updates for mineral resources, production rates and economic analysis.

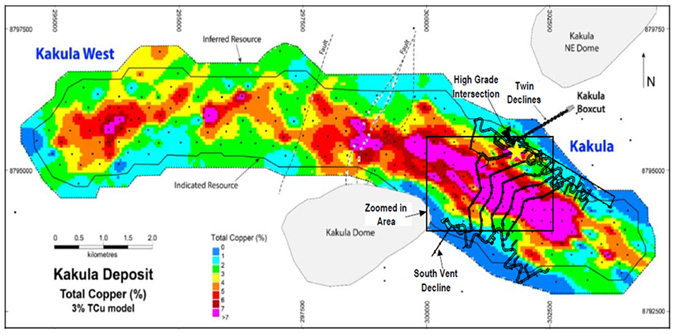

Figure 1: The 13.3-kilometre-long Kakula Deposit showing the first five years of planned underground development and production (in the black box at the eastern end of the deposit) focused on the pink area containing average copper grades greater than 8% copper.

More detail of current underground development progress and planned development over the next three and six months is shown in figures 2, 3 & 4.

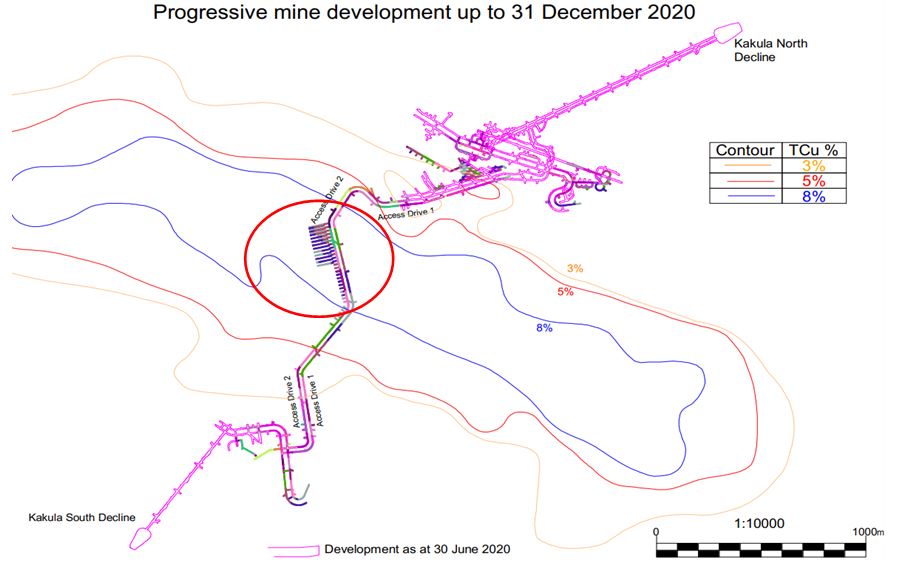

Figure 2: Underground development completed to the end of June (in purple) and scheduled development (green, brown, blue & black) over the next quarter. Shown are the 3%, 5% and 8% copper contours and the location where the northern and southern access drives are scheduled to join by the end of October (red star).

Figure 3: Underground development completed to the end of June (in purple) and scheduled mine development over the three months ending December 31, 2020. Majority of the development during this period will be in the initial drift-and-fill mining area (circled in red) within Kakula’s high-grade zone (+8% copper).

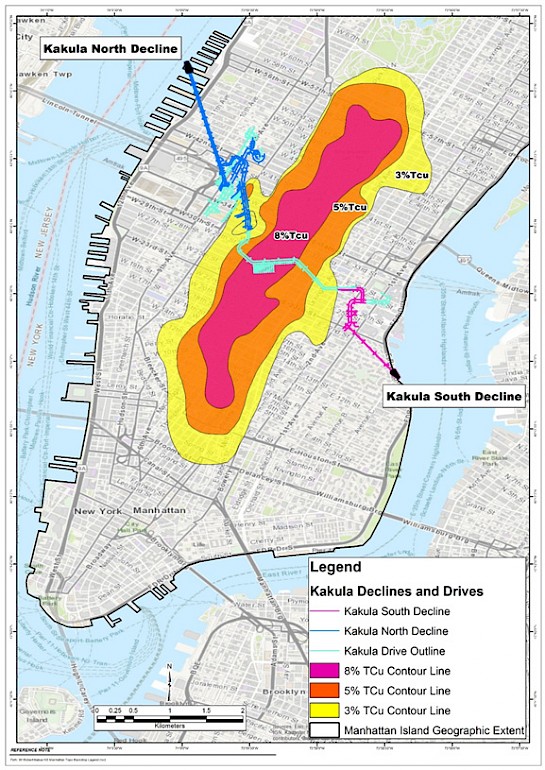

Figure 4: The eastern portion of Kakula Mine ─ representing less than half of the overall 13.3-kilometre-long Kakula Deposit ─ overlain on southern Manhattan Island to give a sense of the enormous scale of the underground operations.

Kakula’s team members (L-R) Timothe Kabeya, Jean Luc Kadita, Epwila Kundjuka, Nkulu Nsungu with one of the project’s newly commissioned Epiroc 282 double-boom, semi-autonomous drill rigs.

Construction progress on the processing plant and other surface infrastructure remains on track for initial production in Q3 2021

Construction of Kamoa’s 3.8-million tonne-per-annum (Mtpa) concentrator plant is progressing well, with more than15,000 cubic metres of concrete being poured to date. Concrete bases for the ball mills, flotation plant and the concentrate thickener have been partially handed over to the mechanical contractor to commence installation work, and steel erection is currently underway in the flotation and thickener areas. Approximately 3,600 tonnes of structural steel had been shipped from China by end of June.

Beijing-based CITIC Construction has been awarded the construction contract for Kakula’s phase 1 backfill paste plant. The backfill plant will be used to blend tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately 55% of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage.

The Electrical & Instrumentation contract was recently awarded to T3 Construction, a leading South African construction company. This is the final major construction contract required for Kakula’s processing and backfill plants.

Construction of the tailings dam has commenced and is progressing well, the aim is to complete most of the earthworks during the dry season before the rainy season starts in November.

Aerial view of ongoing construction of Kamoa’s 3.8 Mtpa processing plant.

Kakula’s processing plant’s flotation circuit under construction.

Structural steel beams that will be used in the processing plant’s flotation circuit that were delivered to the Kakula Mine in early June.

Crews assembling the mill discharge sumps for Kakula’s processing plant.

Clean, sustainable hydro-electric power for Kamoa-Kakula

Construction activities at the Mwadingusha hydro-electric power plant, where all six turbines are being replaced, is progressing well; as is the associated 220-kilovolt (kVA) infrastructure to supply the mine with clean hydro-power. The mine is scheduled to be energized with permanent 220kV hydro-generated power in early 2021, well in time for first copper production.

The temporary construction power supply for the Kakula Mine was recently upgraded, including the commissioning of five new 2MW generators to provide back-up power, and the installation of an 18MW/120kV mobile substation to increase the capacity of grid power available at the mine. This will provide sufficient power until the main 220kV power supply is energized.

Construction of the 220kV supply infrastructure is in progress, including: a new 220kV distribution sub-station for the power utility (SNEL); and a new 35-kilometre, 220kV power line and a consumer substation at Kakula with two 80MW/220kV transformers. The transformers are presently being factory tested and prepared for shipment to site.

A new access road from the city of Kolwezi to the Kansoko and Kakula mines was recently completed and is now open to traffic.

Kamoa-Kakula’s COVID-19 readiness initiatives focused on risk mitigation

More than 3,500 employees and contractors currently are working on site, of which approximately 90% are Congolese nationals. To date, Kamoa-Kakula has had no confirmed COVID-19 cases.

As part of Kamoa-Kakula’s COVID-19 readiness initiatives, the project has procured a polymerize chain reaction (PCR) device from German-based Bosch (similar device to the GeneXpert). The device is scheduled to arrive this week, with an initial supply of 500 tests. The device’s capacity is 15 tests per 24-hour period.

PCR tests are used to directly detect the presence of an antigen, rather than the presence of the body’s immune response, or antibodies. By detecting viral RNA, which will be present in the body before antibodies form or symptoms of the disease are present, the tests can tell whether or not someone has the virus very early on.

Early detection of potential cases based on symptoms and contact tracing is imperative. PCR tests will give the project’s medical team a good indication of who is infected. This allows for fast isolation, and contact tracing of potential additional cases for quarantine.

The project has established a COVID-19 isolation facility at the Kamoa camp. Any suspected or symptomatic cases are moved to this facility, where they are isolated, treated and tested. Once the patient has recovered and is deemed no longer infectious, they can return to work only after an additional quarantine period determined by the project’s medical staff.

As the pandemic evolves, the medical team at Kamoa-Kakula is purposefully reviewing and updating its risk mitigation protocols. The project’s preventative measures are at the highest standard and if there was a case internally, the risk of spreading or cross contamination is very low.

Mumba fish ponds and vegetable farm near the Kamoa-Kakula Project.A significant portion of the project’s local socio-economic initiatives are geared toward food security, education and skills development. The Livelihoods Program at Kamoa-Kakula has developed into a large-scale operation, with hundreds of beneficiaries raising fish, growing maize and vegetables, and selling poultry and honey.

Qualified Persons

Disclosures of a scientific or technical nature regarding the revised capital expenditure and development scenarios at the Kamoa-Kakula Project in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Amos is not considered independent under NI 43-101 as he is the Head of the Kamoa Project. Mr. Amos has verified the technical data disclosed in this news release.

Other disclosures of a scientific or technical nature in this news release have been reviewed and approved by Stephen Torr, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Torr is not considered independent under NI 43-101 as he is the Vice President, Project Geology and Evaluation. Mr. Torr has verified the other technical data disclosed in this news release.

The stockpile grade estimates contained in this release are based upon bulk ore sampling from underground headings. Sampling is done on each heading every second blast and three 5-kilogram samples are taken. The samples are pulverized at the project’s onsite laboratory and analyzed used using a portable XRF (pXRF) instrument. Kamoa Copper has routinely analyzed its exploration drill core for copper using pXRF, in addition to analysis at a commercial laboratory using four acid digest and ICP-OES. This data has demonstrated that pXRF results can be relied upon for grade control and run-of-mine sampling.

Ivanhoe has prepared a current, independent, NI 43-101-compliant technical report for the Kamoa-Kakula Project, which is available on the company’s website and under the company’s SEDAR profile at www.sedar.com:

- The Kamoa-Kakula 2020 Resource Update dated March 25, 2020, prepared by OreWin Pty Ltd., Wood plc, DRA Global, SRK Consulting (South Africa) (Pty) Ltd and Stantec Consulting International LLC.

The technical report include relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Project cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

Information contacts

Investors: Bill Trenaman +1.604.331.9834 / Media: Matthew Keevil +1.604. 558.1034

Forward-looking statements

Certain statements in this release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company, its projects, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results and speak only as of the date of this release.

Such statements include without limitation, the timing and results of: (i) statements regarding Kakula’s first 3.8-million-tonne-per-annum processing plant is scheduled to begin operations in Q3 2021; (ii) statements regarding Kakula’s 2,000-tonne-per-hour ore conveyor system will further increase the mine’s pace of underground development; (iii) statements regarding as Kakula’s underground development progresses over the next few months, the majority of the headings are expected to transition into the high-grade ore; (iv) statements regarding the surface conveyor system is scheduled to be completed by Q1 2021; (v) statements regarding the northern and southern access drives at the Kakula Mine are scheduled to be joined by the end of October 2020; (vi) statements regarding the majority of the underground development during the three months ending December 31, 2020 will be in the initial drift-and-fill mining area (circled in red) within Kakula’s high-grade zone (+8% copper); (vii) statements regarding fabrication of the ventilation fans is scheduled to start this month; (vii) statements regarding the independent Kakula definitive feasibility study (DFS) and an updated Integrated Development Plan for the entire Kamoa-Kakula mining complex is expected to be finalized this month; (ix) statements regarding the mine is scheduled to be energized with permanent 220kV hydro-generated power in early 2021; and (x) statements regarding the new polymerise chain reaction (PCR) device from German-based Bosch is scheduled to arrive this week.

As well, all of the results of the pre-feasibility study for the Kakula copper mine and the updated and expanded Kamoa-Kakula Project preliminary economic assessment constitute forward-looking statements or information, and include future estimates of internal rates of return, net present value, future production, estimates of cash cost, proposed mining plans and methods, mine life estimates, cash flow forecasts, metal recoveries, estimates of capital and operating costs and the size and timing of phased development of the projects. Furthermore, with respect to this specific forward-looking information concerning the development of the Kamoa-Kakula Project, the company has based its assumptions and analysis on certain factors that are inherently uncertain. Uncertainties include: (i) the adequacy of infrastructure; (ii) geological characteristics; (iii) metallurgical characteristics of the mineralization; (iv) the ability to develop adequate processing capacity; (v) the price of copper; (vi) the availability of equipment and facilities necessary to complete development; (vii) the cost of consumables and mining and processing equipment; (viii) unforeseen technological and engineering problems; (ix) accidents or acts of sabotage or terrorism; (x) currency fluctuations; (xi) changes in regulations; (xii) the compliance by joint venture partners with terms of agreements; (xiii) the availability and productivity of skilled labour; (xiv) the regulation of the mining industry by various governmental agencies; (xv) the ability to raise sufficient capital to develop such projects; (xiv) changes in project scope or design, and (xv) political factors.

Forward-looking statements and information involve significant risks and uncertainties, should not be read as guarantees of future performance or results and will not necessarily be accurate indicators of whether or not such results will be achieved. A number of factors could cause actual results to differ materially from the results discussed in the forward-looking statements or information, including, but not limited to, the factors discussed below and under “Risk Factors”, and elsewhere in this release, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

Although the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

The company’s actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors set forth below in the “Risk Factors” section in the company’s Q1 2020 MD&A and its current annual information form.

English

English Français

Français 日本語

日本語 中文

中文