Pre-production ore stockpiles now hold 1.52 million tonnes grading 4.03% copper, containing more than 61,000 tonnes of copper

Record underground development of 2,792 metres completed in December; more than 29.8 kilometres now complete – 10.5 kilometres ahead of plan

Remarkable thickness of the high-grade copper ore in the centre of the Kakula Mine has allowed the expansion of development drifts in this area to 10 metres high by 7.5 metres wide (75 square metres)

Overall progress of Kamoa-Kakula’s first phase, 3.8-Mtpa mining and milling operation now approximately 68% complete; first copper concentrate production continues to on track for July 2021

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun are pleased to announce that underground development at the Kamoa-Kakula Copper Project in the Democratic Republic of Congo (DRC) mined and stockpiled 269,000 tonnes of ore grading 5.36% copper in December from the Kakula and Kansoko mines. The tonnage was 7.6% higher than November, while the copper grade was 10.5% higher.

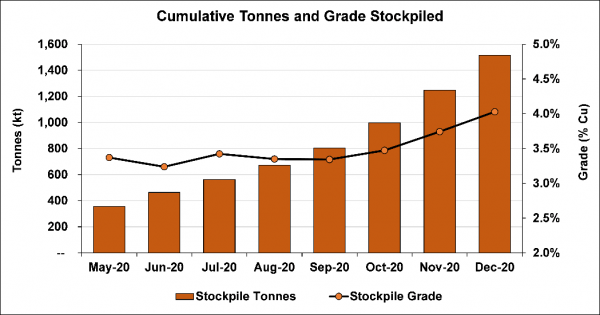

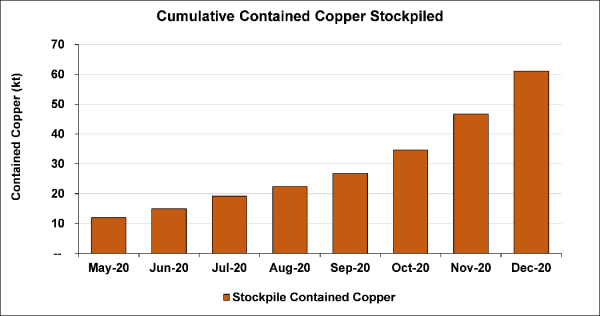

The project’s pre-production surface stockpiles now contain approximately 1.52 million tonnes of high-grade and medium-grade ore at an estimated blended grade of 4.03% copper. Contained copper in the stockpiles increased by approximately 14,400 tonnes in December – a 30.9% increase over November’s production reflecting the increased mining in the ultra-high-grade centre of the Kakula Deposit – to a cumulative total of more than 61,000 tonnes (the current copper price is approximately US$7,900 a tonne).

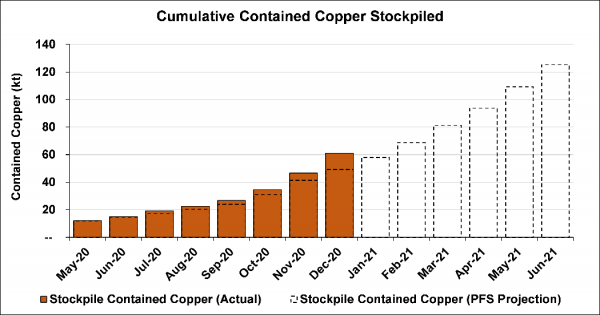

The project is on track to have approximately three million tonnes of high-grade and medium-grade ore stockpiled on surface, holding more than 125,000 tonnes of contained copper, prior to the planned start of processing in July 2021.

Mr. Friedland and Mr. Sun also noted that the project team established another new monthly record for underground mine development in December with a total of 2,792 metres of advancement – 620 metres more than the previous monthly high achieved in October 2020. Another important development milestone was achieved in late December with the second holing of Kakula’s northern and southern access tunnels, establishing additional access to mine Kakula’s high-grade ore in the centre of the orebody grading +8% copper.

“After more than 26 years of continuous efforts, Ivanhoe Mines and its joint-venture partners are less than six months away from initial production at Kamoa-Kakula – the first world-scale copper discovery on the African continent in generations. This year’s transformation marks the beginning of the next chapter of our journey that began in 1994 and has involved thousands of dedicated and talented people,” said Mr. Friedland. “Underground development at the Kakula Mine is well ahead of schedule and construction of the first phase processing plant is on schedule to produce exceptionally high-grade and clean copper concentrates beginning this July. The performance of Kamoa Copper’s multinational management team in successfully navigating the profound logistical challenges posed by the global COVID-19 pandemic has been absolutely outstanding.”

“Our expectations are for continued rising copper prices through 2021 and beyond; as such, the timing of Kamoa Copper’s first production is fortuitous given that the project is scheduled to have ore stockpiles containing more than 125,000 tonnes of contained copper available for processing by July 1st. A rising copper price directly impacts the realizable value of the contained copper in the stockpiles, the cost of which is capitalized,” Mr. Friedland added.

December’s record-setting advancement brings total underground development to approximately 29.8 kilometres – approximately 10.5 kilometres ahead of schedule. The monthly underground development in December was comprised of 2,521 metres at the Kakula Mine and 271 metres at the Kansoko Mine.

Mark Farren, Kamoa Copper’s CEO, commented: “A terrific performance by our mining teams in December and an exceptional way to end 2020. To achieve a record-setting month in the midst of the holiday season is a testament to the commitment and professionalism of our people. The start of 2021 brings with it a sense of excitement and opportunity as we begin to shift our focus from mine development to production.”

“Mining crews recently entered a remarkably thick zone of high-grade ore grading +8% copper in the centre of the Kakula Mine, which has allowed us to enlarge the development drifts in this area to 10 metres high by 7.5 metres wide (75 square metres), and the increase in ore tonnes per metre of development has been substantial,” Mr. Farren added.

Kakula’s combined medium-grade and high-grade ore mined in December was approximately 245,000 tonnes at an average grade of 5.64% copper, including approximately 55,000 tonnes grading 8.75% copper from the +8% copper zone in the centre of the orebody. Mining crews at Kakula are primarily focused on developing the drift-and-fill mining blocks in the high-grade centre of the orebody. Opening up of the mining footprint for these high grade, drift-and-fill mining areas entails, by necessity, development work in areas of low-, medium- and high-grade ore, and is designed to coincide with the start-up of the processing plant in July. This will allow crews to deliver significant tonnage of high-grade ore directly from Kakula’s underground workings to the processing plant.

Kansoko’s combined medium-grade and high-grade ore mined in December was approximately 24,000 tonnes at an average grade of 2.49% copper. Priorities at Kansoko during December were to develop and support major ventilation airways towards the mine’s No. 1 ventilation shaft. Kansoko is being developed by training crews and will be a supplemental source of ore for Phase 2 of the project’s development when the Kakula concentrator processing capacity doubles to 7.6 million tonnes per annum (Mtpa) − currently planned to be commissioned in Q3 2022.

One of Kakula’s high-performing mining crews. Top row (left to right): Mike Ilunga, Aliday Mujinga, Elize Nkulu, Ebrahim Tshikala, Liu Huang and Jean Paul Ndayi. Bottom row: Eric Kaut, Seriphin Lupitshi, Lazare Ilunga and Didier Kaona.

Miners operating a jumbo drill at the face of a high-grade development drift near the centre of the Kakula Mine. Due to the thickness of the copper ore in this area, the drifts are 10 metres high by 7.5 metres wide (32.8 feet high by 24.6 feet wide), or 75 square metres. For perspective, the height of the drift is close to the height of a standard telephone pole. The average grade of ore in this area is 8.75% copper and the tonnage per blast is approximately 1,000 tonnes, more than double the tonnage per blast in a normal drift.

Phase 1 copper production from the Kakula Mine is scheduled to begin in July 2021. Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated average feed grade of more than 6.0% copper over the first five years of operation. Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the Government of the Democratic Republic of Congo (20%).

An independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

December’s ore production was 7.6% higher than November, with monthly copper grade increasing from 4.85% to 5.36%; pre-production surface ore stockpiles now total approximately 1.52 million tonnes grading 4.03% copper

In December, mining crews at Kakula and Kansoko mined and transported to surface stockpiles approximately 269,000 tonnes of ore grading 5.36% copper. This brings the project’s total pre-production high- and medium-grade ore stockpiles to approximately 1.52 million tonnes at an estimated blended grade of 4.03% copper. An additional 622,000 tonnes of low-grade development ore also has been stockpiled on surface.

December’s ore production was approximately 7.6% higher than the 250,000 tonnes grading 4.85% copper mined in November, and approximately 38% higher than the 194,000 tonnes grading 4.01% mined in October.

Chart 1: Cumulative tonnes and grade of pre-production ore stockpiles at the Kakula and Kansoko mines from May 2020 to December 2020.

Chart 2: Growth in contained copper in pre-production ore stockpiles at the Kakula and Kansoko mines from May 2020 to December 2020.

Chart 3: Projected growth in contained copper in the pre-production stockpiles at the Kakula and Kansoko mines up to July 2021. Dotted lines denote projections based on the 2020 pre-feasibility study.

The ore being mined from the northern portion of the Kakula Mine is transported to surface via the conveyor system and placed on a blended surface stockpile that now contains approximately 900,000 tonnes grading an estimated 4.26% copper.

Additional pre-production ore stockpiles are located at the Kakula southern decline (approximately 188,000 tonnes of high-grade ore grading 5.73% copper and 250,000 tonnes of medium-grade ore grading 2.80% copper) and the Kansoko decline (approximately 3,000 tonnes of high-grade ore grading 6.48% copper and 174,000 tonnes of medium-grade ore grading 2.72% copper).

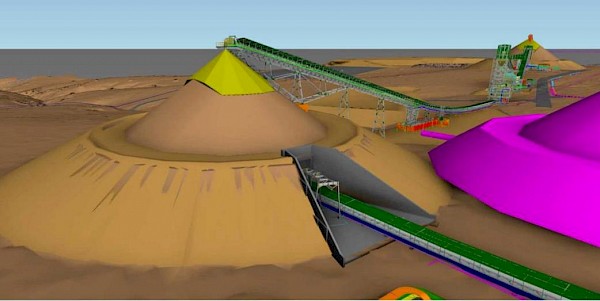

Kakula’s main pre-production stockpiles at the northern declines. The blended stockpiles currently contain approximately 900,000 tonnes grading 4.26% copper.

Kakula southern decline ore stockpiles containing approximately 188,000 tonnes of high-grade ore grading 5.73% copper, and 250,000 tonnes of medium-grade ore grading 2.80% copper.

Kansoko decline ore stockpiles containing 177,000 tonnes grading 2.77% copper, including 3,000 tonnes of high-grade ore grading 6.48% copper.

Bernard Ngoyi, belt attendant, at the Kakula North underground ore conveyor.

Dianne Lukenda, trainer, with a cable-anchor installation team at the Kansoko Mine.

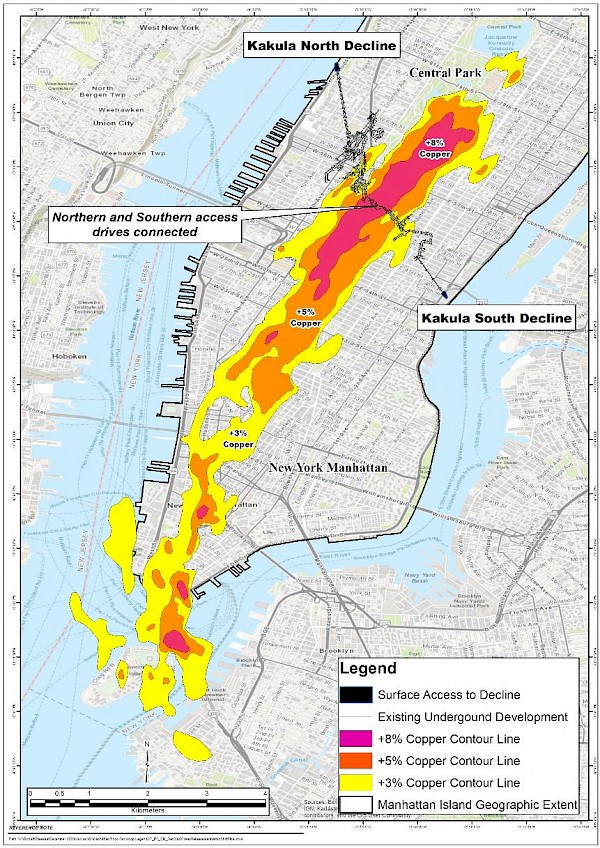

Figure 1: The overall 13.3-kilometre-long Kakula Deposit overlain on southern Manhattan Island to provide a sense of the scale of the deposit.

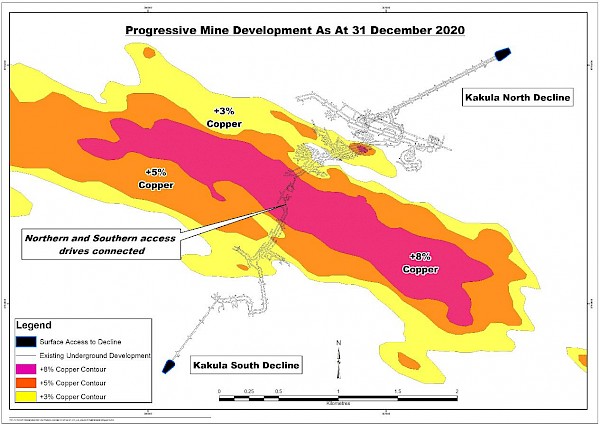

Figure 2: Underground development completed at Kakula Mine to December 31, 2020 (in black).

Construction of the initial 3.8-Mtpa concentrator plant and other surface infrastructure on schedule; earthworks and civil works progressing well for the second 3.8-Mtpa concentrator plant

Overall progress of Kamoa-Kakula’s first-phase, 3.8-Mtpa mining and milling operation (covering mine infrastructure, concentrator plant and surface infrastructure) now is approximately 68% complete, up from 63% last month. Overall construction of the project’s first phase 3.8-Mtpa concentrator plant and associated facilities is advancing rapidly and is approximately 41% complete, up from 35% last month. The concentrator plant remains on track to be mechanically complete in Q2 2021, with first copper concentrate production scheduled for July 2021.

Civil works for the first concentrator plant is effectively complete (30,135 cubic metres of concrete poured from a total of 31,407 cubic metres) with all areas handed over and well advanced in steel, mechanical, piping and platework (SMPP) erection and installation.

A number of areas have been handed over to the electrical, control and instrumentation (EC&I) contractor for electrical installation. EC&I installation is the last activity before construction completion and subsequent commissioning.

Ongoing installation of piping at Kakula’s first 3.8-Mtpa concentrator plant.

Delivery of equipment to site is nearing completion with all structural steel, platework and piping delivered. The last truckloads of electrical cable are on route from the port of Durban, South Africa, and are expected to arrive this month. The sand filter plant and the last shipments of switchgear are scheduled to arrive in February and March 2021, respectively. More than 2,190 truckloads of equipment have been delivered to site.

Less than 680 tonnes (of a total of 4,882 tonnes) of plant structural steel remains to be installed, and 635 tonnes of platework have been installed out of a total of 863 tonnes. All steel and platework is expected to be installed in the next five to seven weeks. With the bulk of the steel structures now complete, the SMPP contractor is focusing on piping and sheeting installation. Approximately 23 kilometres of piping has already been installed.

Electrical installation in a number of areas is progressing well, with the milling area 20% complete and a number of other areas such as crushing, flotation, tailings handling in excess of 10% complete. The initial focus is on cable racking and cable installation – 48,000 metres (48 kilometres) of copper electrical cable have been installed out of a total of 207,000 metres (207 kilometres).

Watch a short fly-over video of the construction of the concentrator plant and other surface infrastructure: https://vimeo.com/495561497/9e42d84cf2

Kakula’s concentrate storage warehouse under construction.

Steel erection for Kakula’s first phase, backfill paste plant is nearing completion with electrical installation underway. The outer steel structure of the plant has been completed including the installation of the gantry crane. Structural steel erection is scheduled to be completed early this year.

The backfill plant will be used to mix tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage.

Ongoing construction of Kakula’s first phase, backfill paste plant.

Construction of the tailings dam is progressing well and is scheduled to be completed well ahead of the required date. Installation of the three tailings lines and the tailings-return water line is nearing completion with 22 kilometres (of a total of 25 kilometres) complete.

The long-lead items for the second 3.8-Mtpa concentrator plant have been ordered and Phase 2 of the project’s development is underway. Bulk earthworks is approximately 20% complete and civil works has started in the stockpile and milling areas.

Excavation of the ball mill foundations for the second 3.8-Mtpa concentrator.

Concrete poured for the ball mill foundations for the second 3.8-Mtpa concentrator.

Paul Kamboya Yav, Assistant Boilermaker, at the Kakula concentrator plant.

Pipefitters Serge Itadi Mushid (left) and Junior Malandji (right), working on the concentrate storage warehouse.

Contractors installing copper electrical cables at the Kakula concentrator plant.

Thomas Ngoyi, scaffold erector with DRC contracting company Majengo, at the Kakula concentrator plant.

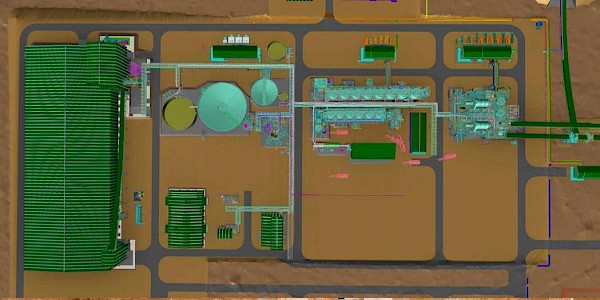

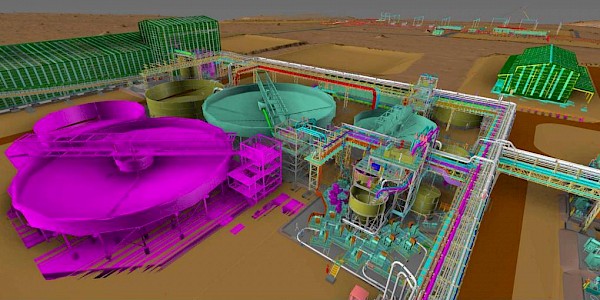

A 3D, overhead illustration of the finished Phase 1, 3.8-Mtpa concentrator plant. The picture

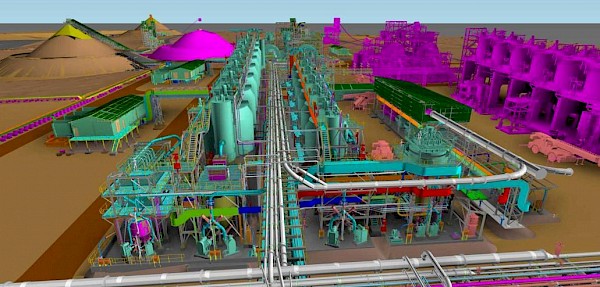

A 3D illustration of the finished ball mills area for the Phase 1, 3.8-Mtpa concentrator, with the next two ball mills for the recently-initiated Phase 2 concentrator plant shown in magenta. The picture

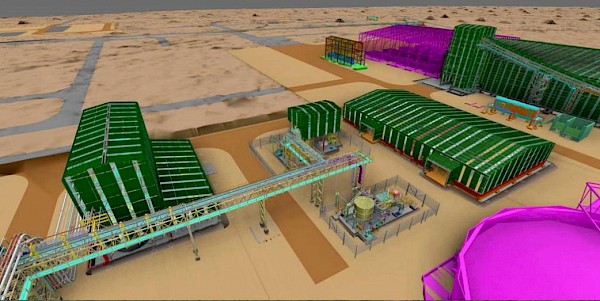

A 3D illustration of Kakula’s initial 3.8-Mtpa concentrator plant, with the recently-initiated Phase 2 3.8-Mtpa processing plant shown in magenta. The picture immediately below shows the currentconstruction progress.

A 3D illustration of the initial high-pressure-grinding-rolls (HPGR) stockpile, with the recently-initiated second HPGR stockpile shown in magenta. The picture immediately below shows the currentconstruction progress.

A 3D illustration of the tailings thickener (larger one in green) and concentrate thickener (smaller one in green), with the concentrate bagging plant shown in the background and the Phase 2 thickeners shown in magenta. The picture immediately below shows the currentconstruction progress.

A 3D illustration of the reagent storage building,bagging plant and concentrate storage building, with Phase 2 shown in magenta. The picture immediately below shows the currentconstruction progress.

A 3D illustration of Kakula’s first phase, finished backfill plant, with the current construction and the initial 3.8-Mtpa concentrator plant in the background shown immediately below. The backfill plant will blend tailings from the concentrator with cement to produce paste backfill that will be pumped into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground.

Watch a short fly-over video of the construction the backfill plant: https://vimeo.com/495562272/bbd5f360b5

Advanced, detailed discussions for the marketing of Kakula’s copper concentrates

Kamoa-Kakula is in advanced, detailed discussions with a number of parties with respect to the sale of its copper concentrates. Kakula is expected to produce an extremely high grade and clean copper concentrate (containing over 55% copper) that will be highly coveted by copper smelters around the world. Metallurgical test work indicates that the Kakula concentrates contain extremely low arsenic levels by world standards – approximately 0.01%.

Kamoa-Kakula now connected to the national power grid, providing clean, renewable 220-kV hydropower; first of six turbines at the refurbished Mwadingusha hydropower plant now synchronized to the national grid

In December, Kamoa-Kakula was connected to the national power grid with the energizing of the 35-kilometre, 220-kilovolt (kV) power line connecting theWestern Dispatch substation in Kolwezi to Kamoa-Kakula, supplying the project with reliable and clean hydro-generated electricity.

Kakula’s main electrical substation and several of the 220-kV power line transmission towers connecting the substation to the national power grid.

Watch a short fly-over video of the construction of the main electrical substation: https://vimeo.com/495561964/e87607bb4c

Ivanhoe Mines Energy DRC is pleased to announce that the first of six new turbines at the Mwadingusha hydropower plant was synchronized to the national electrical grid in December. Commissioning of the plant’s remaining five generating units, in sequence, soon will begin to ensure that Kamoa-Kakula’s power requirements are met ahead of the commissioning of the concentrator plant. The fully-refurbished hydropower plant is expected to deliver approximately 72 megawatts of power to the national grid.

Ivanhoe Mines Energy DRC achieved a significant milestone in December when the first of six turbines at the Mwadingusha hydropower plant began delivering clean, hydropower to the national electrical grid.

COVID-19 prevention initiatives continue to focus on risk mitigation

Kamoa-Kakula’s prevention measures remain strictly enforced, with further prevention being the focus while the world responds to the latest COVID-19 strain. Rigorous testing, physical distancing, wearing of face masks, frequent hand washing and contact-tracing measures are still in place to protect the safety and health of the workforce and community members.

The project has a well-established COVID-19 isolation facility at the Kamoa Camp. Suspected cases and symptomatic patients are moved to this facility, where they are isolated, tested and treated. Once patients have recovered and are deemed no longer infectious, they can return to work only after an additional quarantine period determined by the project’s medical staff.

Kamoa-Kakula has successfully sourced the latest COVID-19 rapid diagnostic tests (RDT) that test for antigens (the presence of viral particles). The tests are being used by the medical team at Kamoa-Kakula to screen all site arrivals and travellers. Test results are received within an average of 20 minutes, which further enhances the preventative measures already in place.

As the pandemic evolves, the medical team at Kamoa-Kakula continues to review and update its risk mitigation protocols. The project’s preventative measures are at the highest international standards, and should there be a case internally, the risk of spreading or cross-contamination is considered to be very low.

Kamoa-Kakula’s contractors accommodations and recreation facilities.

Blasting assistants, Augustine Sondash (left) and Fiston Maloba (right) in the Kakula Mine.

The Mumba community fish farm and vegetable garden, a Kamoa-Kakula Sustainable Livelihoods project designed to enhance food security and the living standards of the people who reside within the project’s footprint.

The new school in the village of Muvunda, a community initiative to increase education opportunities for families living near the Kamoa-Kakula Project.

SeamstressProsperine Kazadimake sewing new Kamoa Copper uniforms at the Kamoa Sewing Project, another Kamoa-Kakula Sustainable Livelihoods project.

Qualified Persons

Disclosures of a scientific or technical nature regarding development scenarios at the Kamoa-Kakula Project in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Amos is not considered independent under NI 43-101 as he is the Head of the Kamoa Project. Mr. Amos has verified the technical data disclosed in this news release.

Other disclosures of a scientific or technical nature regarding the stockpiles in this news release have been reviewed and approved by George Gilchrist, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Gilchrist is not considered independent under NI 43-101 as he is the Vice President, Resources of Ivanhoe Mines. Mr. Gilchrist has verified the other technical data disclosed in this news release.

The stockpile grade estimates contained in this release are based upon bulk ore sampling from earlier underground headings, and vertical channel sample profiles from recent development. Bulk ore sampling was done on each heading every second blast and three 5-kilogram samples were taken. Since the beginning of October 2020, channel sample profiles are the primary data informing the stockpile grade estimates. These are cut approximately 15 metres apart in 1-metre vertical increments across the full vertical exposure using a handheld grinder, with a 100-to-150-gram sample collected. The samples are pulverized at the project’s onsite laboratory and analyzed using a portable XRF (pXRF) instrument. Kamoa Copper has routinely analyzed its exploration drill core for copper using pXRF, in addition to analysis at a commercial laboratory using four acid digest and ICP-OES. This data has demonstrated that pXRF results can be relied upon for grade control and run-of-mine sampling.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Project, which is available on the company’s website and under the company’s SEDAR profile at www.sedar.com:

- Kamoa-Kakula Integrated Development Plan 2020 dated October 13, 2020, prepared by OreWin Pty Ltd., China Nerin Engineering Co., Ltd., DRA Global, Epoch Resources, Golder Associates Africa, KGHM Cuprum R&D Centre Ltd., Outotec Oyj, Paterson and Cooke, Stantec Consulting International LLC, SRK Consulting Inc., and Wood plc.

The technical report includes relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Project cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal joint-venture projects in Southern Africa: the development of major new, mechanized, underground mines at the Kamoa-Kakula copper discoveries in the DRC and at the Platreef palladium-platinum-nickel-copper-rhodium-gold discovery in South Africa; and the extensive redevelopment and upgrading of the historic Kipushi zinc-copper-germanium-silver mine, also in the DRC. Kamoa-Kakula is expected to begin producing copper in July 2021 and, through phased expansions, is positioned to become one of the world’s largest copper producers. Kamoa-Kakula and Kipushi will be powered by clean, renewable hydro-generated electricity and will be among the world’s lowest greenhouse gas emitters per unit of metal produced. Ivanhoe also is exploring for new copper discoveries on its wholly-owned Western Foreland exploration licences in the DRC, near the Kamoa-Kakula Project.

Information contacts

Investors: Bill Trenaman +1.604.331.9834 / Media: Matthew Keevil +1.604.558.1034

Forward-looking statements

Certain statements in this release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company, its projects, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results and speak only as of the date of this release.

Such statements include without limitation, the timing and results of: (i) statements regarding the Kamoa-Kakula Project is on track to have approximately three million tonnes of high-grade and medium-grade ore stockpiled on surface, containing more than 125,000 tonnes of copper, prior to the planned start of production in July 2021; (ii) statements that the risk of the risk of spreading or cross-contamination of COVID-19 at the Kamoa-Kakula Project is considered to be very low; (iii) statements regarding the expectation that Phase 2 of the project’s development when the Kakula concentrator processing capacity doubles to 7.6 Mtpa is to be commissioned in Q3 2022; (iv) statements regarding Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated average feed grade of more than 6.0% copper over the first five years of operation; (vi) statements regarding Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year; (vii) statements regarding based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes; (viii) statements regarding Kamoa-Kakula will be among the world’s lowest greenhouse gas emitters per unit of copper produced; (ix) statements regarding approximately one half of the mine’s tailings will be sent back underground; (x) statements regarding Kakula is expected to produce an extremely high grade and clean copper concentrate (containing over 55% copper and extremely low arsenic levels by world standards – approximately 0.01%) that will be highly coveted by copper smelters around the world; and, (xi) statements regarding the fully-refurbished Mwadingusha hydropower plant is expected to deliver approximately 72 megawatts of power to the national grid.

As well, all of the results of the Kakula definitive feasibility study, the Kakula-Kansoko pre-feasibility study and the Kamoa-Kakula preliminary economic assessment, constitute forward-looking statements or information, and include future estimates of internal rates of return, net present value, future production, estimates of cash cost, proposed mining plans and methods, mine life estimates, cash flow forecasts, metal recoveries, estimates of capital and operating costs and the size and timing of phased development of the projects. Furthermore, with respect to this specific forward-looking information concerning the development of the Kamoa-Kakula Project, the company has based its assumptions and analysis on certain factors that are inherently uncertain. Uncertainties include: (i) the adequacy of infrastructure; (ii) geological characteristics; (iii) metallurgical characteristics of the mineralization; (iv) the ability to develop adequate processing capacity; (v) the price of copper; (vi) the availability of equipment and facilities necessary to complete development; (vii) the cost of consumables and mining and processing equipment; (viii) unforeseen technological and engineering problems; (ix) accidents or acts of sabotage or terrorism; (x) currency fluctuations; (xi) changes in regulations; (xii) the compliance by joint venture partners with terms of agreements; (xiii) the availability and productivity of skilled labour; (xiv) the regulation of the mining industry by various governmental agencies; (xv) the ability to raise sufficient capital to develop such projects; (xvi) changes in project scope or design; and (xvii) political factors.

Forward-looking statements and information involve significant risks and uncertainties, should not be read as guarantees of future performance or results and will not necessarily be accurate indicators of whether or not such results will be achieved. A number of factors could cause actual results to differ materially from the results discussed in the forward-looking statements or information, including, but not limited to, the factors discussed below and under “Risk Factors”, and elsewhere in this release, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

Although the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

The company’s actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors set forth below in the “Risk Factors” section in the company’s Q3 2020 MD&A and its current annual information form.

English

English Français

Français 日本語

日本語 中文

中文